Caustic Soda Prices Rise in November on Strong Demand from Various End-User Industries

Owing to a strong surge in demand across various industries globally, the prices of caustic Soda leapt to a significant price range recently. The PVC market has been oscillating on a downswing for quite some time now. Hence, due to its less demand, the production of PVC was down the slope. However, given the demand for caustic Soda has sprung, the production of PVC has attained momentum, too, as caustic Soda is the by-product of PVC production.

China, India, and Southeast Asia have experienced a significant decline in the prices as it fell by approximately 60 per cent as per ChemOrbis Price Index since the towering peaks in the prices last year in the first half of October.

Request Access For the Latest Price Trends of Caustic Soda

Hence, the rise is noteworthy and has pumped the otherwise slumped market of Caustic Soda.

Although a little silver lining could be seen in Europe in April 2022 concerning the decrepit prices, the slight caper was just as low as 15 percent.

Caustic Soda Prices in India

Caustic Soda prices in India received a boost from the rise in Aluminium production. Additionally, the Northward price trend of Caustic Soda was driven by escalating export offers and limited availability of stocks recently. Caustic Soda price trajectory was also influenced by increased downstream output and a reduction in custom duty on Caustic Soda. In response, domestic producers raised their prices to maintain strong margins, given the improving buying momentum in downstream industries. As a result, the price of Caustic Soda Flakes surged by almost more than 6% in the Indian market in recent weeks.

PVC Production Lunged on the Back of Firmer Caustic Soda Demand

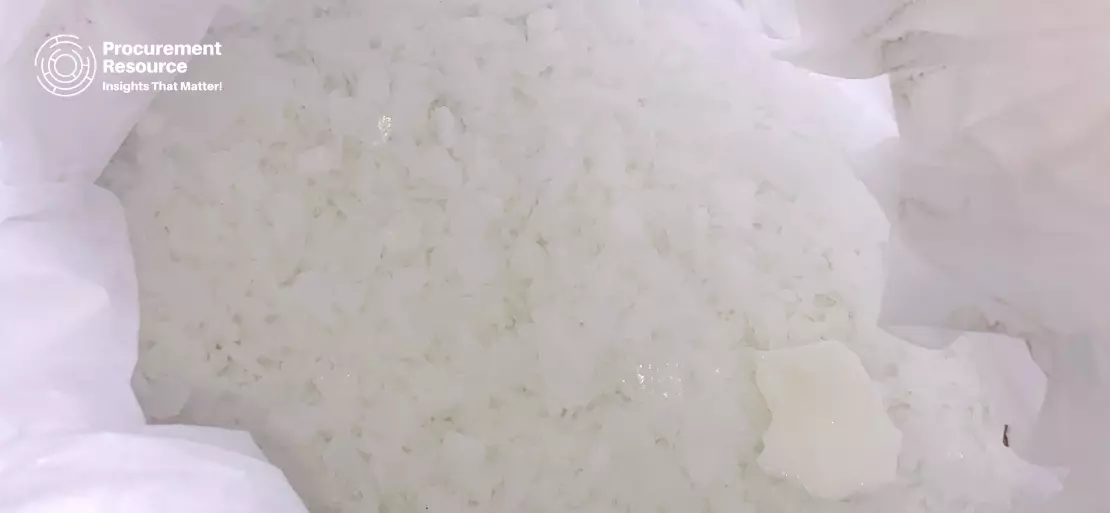

Chlor Alkali is the principal process behind NaOH or caustic Soda production. In the Chlor Alkali process, electricity is passed through the brine, a mixture of NaCl dissolved in water (Common salt mixed in water). Once the electricity is passed through, the ions are dissociated into sodium and chloride ions, with sodium ions reacting with -OH ions to form sodium hydroxide/Caustic Soda. Chlorine is also obtained from this process, which implies the production of VCM and PVC (as chlorine forms a significant reactant material in PVC production).

Therefore, higher caustic soda production would also mean a higher production of PVC- Poly Vinyl Chloride. As per the market experts, as much as 30-40 per cent of the produced chlorine in the Chlor Alkali process goes directly into the PVC production in Vinyl plants.

Drivers of Higher Demand for Caustic Soda

The recoup in the fate of caustic soda prices could be attributed to the pulp and paper industry, where caustic Soda is used as a significant entity in packaging manufacturing. Apart from that, the soap and detergent industries have notably substantiated the plummeting demand for caustic soda due to the pandemic and the situations that have considerably changed.

Adding to the explanation of the slump, caustic soda is extensively put to use in the meat and drink industries, that have already seemed to have enfeebled and decrepitated due to inflation, supply chain impediments, and skyrocketing costs. Hence, the slowed-down demand could be evaluated understandably.

Read More About Caustic Soda Production Cost Reports - Get Free Sample Copy in PDF

Although the primary usage of Caustic Soda finds itself in the alumina-producing industries, the demand pace could not be kept consistent due to disruptions in the supply chain and faltered logistics. The overall dampening of the alumina production thus translated to the debacle in Caustic soda requirements.

A paucity of Caustic Soda Supply

Producers and suppliers of Chlor-alkali have been assuaging production across the world, ensuring control of the supply chain. As a consequence, there has been a decline in the associated and entwined production of caustic Soda as well. Adding to that, Westlake, one of the most prominent producers of caustic Soda in the USA, has coerced the production owing to its declaration of force majeure. Along similar lines, European producers have held their production back, considering heightening utility costs.

Moreover, the demand wave for caustic Soda has surpassed the one for PVC. This clearly suggests the asphyxiating supplies compared to the respiring demands.

According to Procurement Resource, the hike in Caustic Soda can inferentially be pinned on the fulcrum of ample PVC demands. Since more involvement in the Chlor-alkali process would mean more chlorine generation, it has to be used in the production of PVC. The added production of PVC and lengthening demand for caustic Soda is thus creating a demand dichotomy in both products.