The Rise of the Indian Steel Sector

India is the world’s second largest steel producer, and the growth of the Indian steel industry has been aided by the easy domestic availability of raw materials, like iron ore and cost-effective labour. Therefore, the steel sector is a major contributor to India’s manufacturing output. India’s steel production reached 111.2 million tons in the year 2019, and in the next few years, the steel industry is likely to ameliorate.

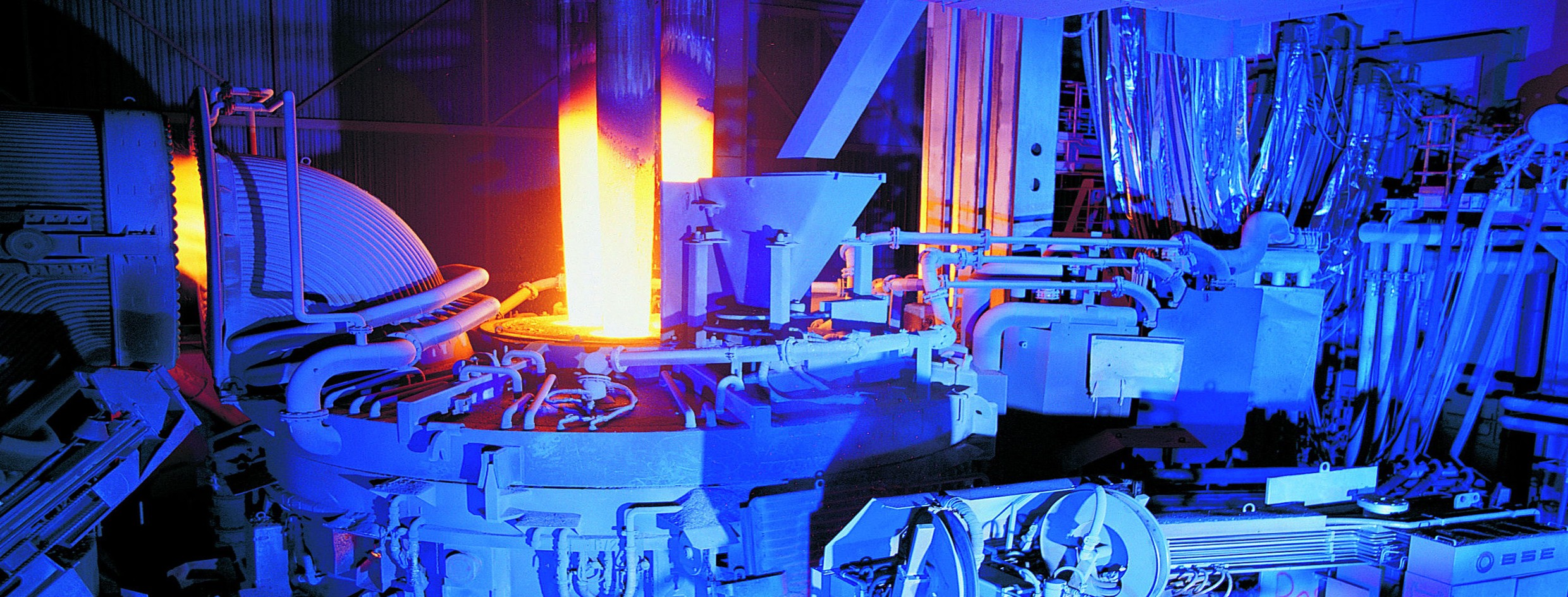

The Indian steel industry has always strived towards continuous modernisation, upgrading older plants to modern facilities in order to achieve higher efficiency levels. Most of the companies in the industry are focusing on modernisation and expansion of plants, adding state-of-art facilities. As India is a developing country and one of the fastest growing economies of the world, the demand for steel is likely to upsurge in the region owing to the growing focus to scale-up the infrastructure and construction processes across the country.

Major Investments in the Steel Sector

The steel industry associated with the mining and metallurgy sectors has seen major investments and developments in 2019 and 2020. In December 2019, Arcelor Mittal acquired Essar steel at INR 42,000 crore and formed a joint venture with Nippon Steel Corporation. In February 2020, GFG Alliance acquired Adhunik Metaliks and its arm Zion Steel for INR 425 crores, making its entry into the steel market of India.

Apart from these investments, the production capacities too saw an upsurge over a period of time. For example, the production capacity of SAIL is anticipated to hike from 13 MTPA to 50 MTPA by 2025, with an estimated total investment of USD 24.88 billion.

JSPL Production Increase

The steel production capacity of JSPL is estimated to increase by 19% in the year 2020 to March 2021. The firm has been witnessing a steady rise in the demand for steel and is expecting an eight-fold increase in the export orders. The company is estimated to export 2.5 million tons of steel in 2020/21, up from 300,000 tons the previous year. Meanwhile, JSPL has already shipped more than half of its exporting target for this year.

This was made possible due to the higher orders from the world’s top consumers, such as China, Vietnam, Europe, and Saudi Arabia. Due to the further boosting of steel demand in China, Indian steel mills more than doubled their exports in April-July. The deals pertaining to the sales of steel took place amidst the rising tension between New Delhi and Beijing over the LAC.

Demand in the Defence Sector

The demand for steel in the defence sector has been driving the Indian steel market. This demand is further accelerated by the need for alloys in order to carry out the shipbuilding projects and other activities. India is the sixth biggest defence spender in the world and is focussing on indigenous manufacturing. This encouragement is further boosted by the rising tensions between Indo-China border disputes.

There has been an unexpected increase in the demand for steel in the defence sector. India’s rising focus on domestic manufacturing in the defence sector has further aided the steel sector as the Ministry of Defence has unveiled several products manufactured in India over the last two years like the composites Sonar dome, a Portable Telemedicine System (PDF) for Armed Forces, HAL Tejas Light Combat Aircraft, Penetration-cum-Blast (PCB), and Thermobaric (TB) ammunition specially designed for Arjun tanks, a heavyweight torpedo, Varunastra, manufactured with 95% locally sourced parts, and medium range surface to air missiles (MSRAM).

India is accelerating towards massive defence modernisation, under which ships, armoured vehicles and helicopters are to be built in the country, as opposed to being imported. Therefore, the domestic market seems very promising and the demand for steel is likely to upsurge after October 2020, with 80% of the overall steel sales taking place within India.