Product

Acrylic Acid Price Trend and Forecast

Acrylic Acid Price Trend and Forecast

Acrylic Acid Regional Price Overview

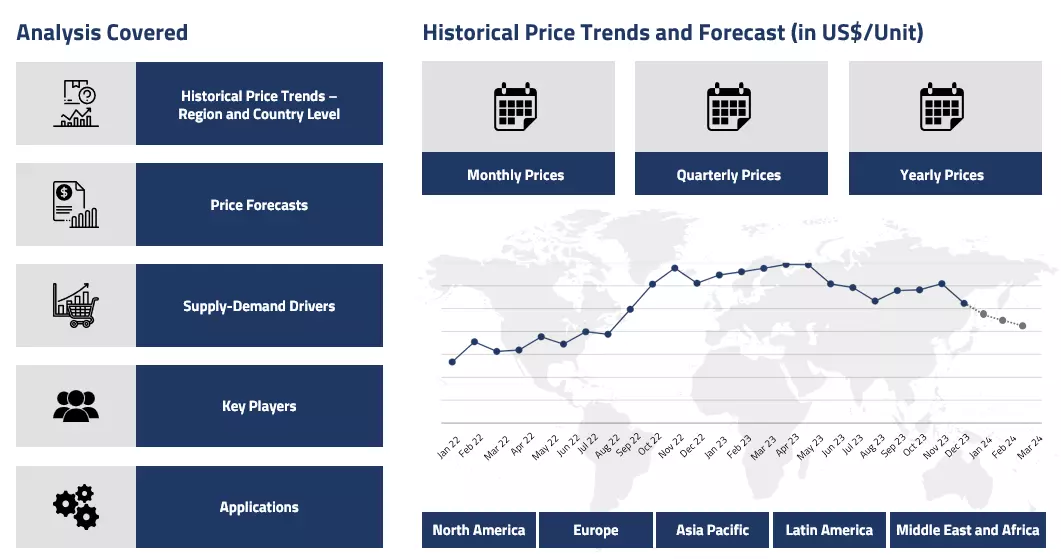

Get the latest insights on price movement and trend analysis of Acrylic Acid in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Acrylic Acid Price Trend for the Q4 of 2024

Asia

In Asia, Acrylic Acid prices demonstrated an upward trajectory throughout Q4’24, particularly in China and Southeast Asian markets. The fourth quarter began with moderate price increases, driven by tight supply conditions as several manufacturers underwent planned maintenance. Chinese markets saw stronger gains, supported by rising propylene feedstock costs and reduced operational rates at major facilities.

Acrylic Acid Price Chart

Please Login or Subscribe to Access the Acrylic Acid Price Chart Data

The market dynamics shifted notably in December when improved supply availability, following the restart of previously offline capacities, led to some price corrections. However, the overall trend remained bullish due to steady downstream demand from the coatings and adhesives sectors.

Europe

The European Acrylic Acid market experienced relatively stable pricing in Q4, though with some fluctuations. The quarter started with modest price increases as producers attempted to improve margins amid elevated production costs. However, the momentum was limited by subdued demand from key end-use industries. The region faced pressure from competitive Asian imports, which influenced pricing strategies of local producers. Towards the end of the quarter, prices showed signs of softening as downstream buying interest remained tepid and inventory levels were sufficient to meet market requirements.

North America

North American markets witnessed a mixed trend during Q4’24. The quarter began with firm pricing supported by healthy demand from the construction and automotive sectors. However, as the quarter progressed, prices began to plateau due to increased market competition and adequate supply levels. The region saw some impact from global market dynamics, particularly from Asian exports. Producer margins remained under pressure throughout the quarter due to volatile feedstock costs, though improved production rates helped maintain market stability.

Analyst Insight

According to Procurement Resource, the Acrylic Acid market is expected to remain relatively balanced, with potential upward pressure from recovering downstream demand and feedstock costs. However, new capacity additions scheduled in Asia could influence global market dynamics and pricing trends.

Acrylic Acid Price Trend for the Q3 of 2024

Asia

The prices of acrylic acid showed a fluctuating trend in the Chinese market. At the start of the quarter, some of the plants were undergoing maintenance leading to a decline in the supply, supporting the other companies to raise prices. The price of feedstock propylene fluctuated narrowly, which provided slight the cost support to the acrylic acid prices. The demand side was comparatively weak as market atmosphere for new orders was average and purchases were made on demand.

Downstream buyers were cautious about not purchasing high prices raw materials. This slow and average terminal demand made it harder for suppliers to maintain the price rise. With this, the acrylic acid prices saw a slight rise in July, and later stabilised in late September after a tepid movement in rest of the quarter. Overall, a consolidated price trend was observed for acrylic acid during the third quarter of 2024.

Europe

During the third quarter of 2024, The acrylic acid prices showed a fluctuating trend in the European markets. Acryliac acid industry in the region faced challenges primarily driven by weak demand from the construction industry, especially in key regions like Germany. The economic slowdown and high inflation dampened market confidence, leading to cautious investment behaviors. Although production costs declined due to lower raw material prices, this did not improve market conditions, as reduced demand led to falling product prices.

Additionally, adverse weather events in Eastern Europe strained the construction sector, suggesting a continued bearish trend for acrylic acid prices during this period. Some production companies decided to consolidate operations in Europe becasuse of declining demands and increasing operational costs. One such was Saudi Arabian Basic Industries Corporation, which announced plans to shut some plants in the region. Overall, a bearish outlook was observed.

North America

The prices of acrylic acid depicted a volatile trajectory in the North American market. The prices of feedstock, propylene, fluctuated but within limited range providing the cost support needed to pull the prices up. The demand from downstream sectors such as paints and coatings was slow but promising. The average demand could not maintain the rise in the price forcing them to fall. Hence, the prices showed a fluctuating trajectory in the North American market. Meanwhile, the eye of hurricane Francine approached the coast in September, several production companies had to shut down their plants in Louisiana, creating a supply crunch in the region.

Analyst Insight

According to Procurement Resource, the price of acrylic acid is expected to fluctuate in the coming months depending on the demand from downstream sectors such as paints and coatings, which is slow but consistent.

Acrylic Acid Price Trend for the Q2 of 2024

Asia

The Chinese market of acrylic acid witnessed oscillating market dynamics during the Q2 of 2024. In the first month of the quarter, the prices inclined at a gradual pace, supported by strong downstream demand from industries such as food, dairy, and pharmaceuticals and limited production activities. However, at the end phase of this month, the fluctuations in the raw material prices stabilized the acrylic acid prices.

This stable trajectory of acrylic acid prices was only momentary as, in subsequent months, the cost of propylene declined, decreasing the overall production expenditure. The supply sector worked efficiently despite some production shutdowns. The market momentum grew so slowly that many enterprises had to offer huge discounts in order to keep the demand for the commodity above par. Overall, the second quarter was characterized by an initial price rise due to strong demand and tight supply, followed by stabilization and consolidation as cost pressures eased and demand normalized.

Europe

The first two months of the second quarter of 2024 proved favorable for the European market of acrylic acid as the price inclination was driven by substantial gains registered by its downstream industries. The overall momentum of the chemical industries improved during this phase as the expansion of manufacturing activities after the dormant winter season supported the demand for the commodity.

However, in this phase, although the domestic demand was enough to push the acrylic acid prices in the northward direction, the exports to China and some other key regions declined slightly, concerning the traders for the next quarter. Also, towards the end of the quarter, the pace of growth of acrylic acid prices slowed down with the stabilization of supply-demand equilibrium. Conclusively, throughout this period, sectors like paints and coatings showed marginal demand improvements while the construction industry and other sectors, such as paper and recovered fiber markets, continued to face challenges.

North America

In the second quarter of 2024, the price trend of acrylic acid in the US saw significant fluctuations primarily due to changing dynamics in the propylene market. In the early phase of the first month, the acrylic acid market experienced a marked decline due to the ill consequences of an oversupply of feedstock and weak demand from key downstream activities. As propylene prices dropped significantly, reaching a low by mid-April, the cost support for acrylic acid weakened.

Despite sellers attempting to attract buyers with lower prices, demand remained muted due to subdued manufacturing activity in industries. Moving into May and June, the acrylic acid market showed signs of stabilization as propylene prices began to recover slightly. This was partly due to seasonal adjustments and a marginal improvement in downstream demand. However, the overall sentiment remained cautious, with the market closely monitoring any potential disruptions and changes in propylene sectors.

Analyst Insight

According to Procurement Resource, the price trend of Acrylic Acid is expected to bear the oscillations observed in its feedstock propylene market activities and changes in the procurement rates of downstream industries.

Acrylic Acid Price Trend for the Q1 of 2024

Asia

Market prices for acrylic acid were observed to fluctuate throughout the discussed period of Q1’24. The price graph showed very confined movements as the prices wavered within a closed limit. The market started weak in China at the beginning of January as a dull demand outlook kept pushing the price trajectory downwards.

Even when the crude oil and feedstock prices increased it did not affect the prices much as the procurement was still largely unsatisfactory. Troubled by these dull demands, the suppliers acquired a wait-and-watch approach and controlled the bulk purchases to manage the market from the supply’s end. It did help a little as the rates started to improve as the quarter end approached; however, the market sentiments still remained largely muted.

Europe

Acrylic acid prices showcased a very mixed price trajectory during the first three months of the year 2024. The first half of Q1 saw a dwindling pattern as the inventory stocks kept maintaining their dominance over a quiet downstream demand pattern. The excess stocks kept pressuring the suppliers to cut down the prices in order to maintain some product movement.

It was only after the production prices hiked in later months and the feedstock propylene costs increased that the market felt some cost support. Suppliers didn’t order much, anticipating lowered demands. This move helped as the prices then started to improve a little in the second half of the quarter. Overall, a varying price graph was witnessed.

North America

The North American acrylic acid market was not much different from its Asian and European counterparts. The prices were observed to be trembling here too for the most period. A dull demand from the downstream sector drove the market for some time at the beginning of Q1. And then the raised crude oil prices started to show their effect. The Red Sea freight issues and other geopolitical tensions also kept disturbing the trading sentiments in the American region. Overall, a muted market performance was experienced.

Analyst Insight

According to Procurement Resource, Acrylic Acid price trends are likely to remain oscillating in the coming months as well; not much change is anticipated in the current price trajectory.

Acrylic Acid Price Trend for the October - December of 2023

| Product | Category | Region | Price | Time Period |

| Acrylic Acid | Chemicals | USA | USD 1500/MT | Dec'2023 |

| Acrylic Acid | Chemicals | Europe | USD 1400/MT | Dec'2023 |

Stay updated with the latest Acrylic Acid prices, historical data, and tailored regional analysis

Asia

In October, the acrylic acid market faced a consistent decline marked due to a fall in raw material propylene prices. The traders faced challenges from weak downstream demand and a lack of acrylic acid inquiries. During the mid-phase of this quarter, unit shutdowns of several units put additional pressure on the traders. However, the market reversed during the end phase of the quarter as the downstream industries started showcasing interest in the acrylic acid market, and they dried up the existing inventories quickly, which acted as a green signal for the traders.

Europe

In the European market, the upward trajectory of the upstream propylene prices and the rise in trading activities helped the acrylic acid market in the initial months of the third quarter. This price surge was influenced by disruptions in trading activities, depleting inventories, and increased costs in the upstream market. However, the weak demand scenario during the fourth quarter of 2023 exerted pressure during the end phase and restricted the upward movement of acrylic acid prices.

North America

In the USA, the rise in acrylic acid prices during the Q4 of 2023 was supported by increased costs in its upstream propylene market. Further, the drought-like conditions in the Panama Canal led to port congestion and disrupted the supply-demand balance. On the other hand, the downstream paints and coating sector in the USA showcased persistent growth in demand for acrylic acid, causing a rise in the prices of acrylic acid.

Analyst Insight

According to Procurement Resource, the price trend of Acrylic Acid are expected to experience oscillations as the demand from the downstream paints and coatings industries is slow but, at the same time, is consistent.

Acrylic Acid Price Trend for the July - September of 2023

Asia

The third quarter of 2023 resonated positively with the Acrylic Acid market trend. With India trying to maintain its growth momentum and China attempting to take their economic situations to pre- Covid times, the demands posed by acrylic acid-consuming sectors like detergents, chemicals, textiles, etc., supported the positive market outlook for Acrylic Acid.

Acrylic acid’s prices closed the third quarter at around 1425 USD/MT (CIF, India) in Sept’23 after starting at about 1395 USD/MT (CIF, India) in July’23 in the Indian domestic market. Furthermore, the Chinese domestic market closed the third quarter at about 885 USD/MT after starting at around 864 USD/MT in July’23. Overall, a positive market analysis was recorded for the Acrylic Acid during the said period.

Europe

In contrast with the inclinations in the Asian market, the Acrylic Acid prices observed a sliding trend in the European region during Q3’23. Inflation caused by the Russian invasion of Ukraine still impacted the trade sentiments, especially in the European Acrylic Acid market. With dull demands and glutted supplies, the Acrylic Acid price graph kept pointing downwards for the entire period of discussion.

North America

A mixed market behavior was observed in the American region towards the Acrylic Acid price trend. After mimicking the European trend of instability in the initial phase of the third quarter because of economic uncertainties in the region, the suppliers exhibited a little cautious behavior in the latter part of the quarter by controlling the influx of supplies. Overall, wavering price trend were observed for Acrylic Acid during the given time period.

Analyst Insight

According to Procurement Resource, positive fluctuations are anticipated for the Acrylic Acid market trend going forward as the downstream demands will continue to be the primary driving factor.

Acrylic Acid Price Trend for the First Half of 2023

Asia

The price trend for acrylic acid fluctuated in the Asian market throughout the first two quarters of 2023. In January the prices stood at 1407 USD/MT (CIF, India) and from there gradually declined till May averaging 1310 USD/MT (CIF, India). The prices then recovered marginally in June’23 and finally stood around 1342 USD/MT (CIF, India).

This oscillation in the prices was due to an uneven trend in demand from end-user industries and an increase in competition from other sectors. In addition to this, a general economic slowdown was also observed in the Asian market which further aided the falling price trend for acrylic acid.

Europe

In European countries, the prices of acrylic acid struggled throughout the first two quarters of 2023 as the trading activities were hampered in the region. The European nations looked forward to decreasing their dependency on Asian imports especially from China to strengthen its commercial activities and thus the prices of acrylic acid faced southwards. In addition to this, the level of inventories rose as a result of oversupply from the East Asian sector along with low consuming behavior from the downstream sector that further aided in the declining trajectory of the prices.

North America

The acrylic acid market fluctuated in the North American region in the first half of 2023. The price trend were influenced by declining demand from paints, coatings, and related industries.

The upstream market was also dim in terms of demand for acrylic acid in both domestic and regional markets. The supply, however, remained strong in the region and thus the rise in inventories further contributed to the falling prices. Further, the cheap imports from the Chinese market amid subdued demand have exerted tremendous pressure on the international chemical pricing fundamentals.

Analyst Insight

According to Procurement Resource, the price trend for acrylic acid are estimated to fluctuate in the upcoming quarter as the demand from the end-user sector seems feeble while the production rates remain stagnant. Inventory destocking and weak demand from certain sectors will linger through most of 2023.

Acrylic Acid Price Trend for the Second Half of 2022

Asia

The price of acrylic acid fell throughout the Asia-Pacific region during the said period. The upstream production and feedstock costs stabilized causing the industries to churn out products faster than the demand leading to stockpiling of products in the market. The market was still recovering from the covid related restrictions and supply shortages; hence the sentiments were shrouded by the fears of a global recession. The demand from the downstream paints and adhesives sectors was minimum. The price of acrylic acid averaged 1025 USD/MT (CIF, India) towards the end of December’22.

Europe

The decreasing prices of feedstock propylene and falling inquiries from the market caused the price trend for acrylic acid to tip towards the lower side of the scale. The economic downturn coupled with the looming speculations of recession has further reduced the offtakes from the market. The dwindling demand for acrylates further added to this trend causing acrylic acid prices to average 1465 USD/MT (CIF, France) in December’22.

North America

The price trend in the US domestic market followed the global outlook. With muted transitions and stockpiling of products in the market acrylic acid prices declined averaging 1318.80 USD/MT ( CIF, USA) in September’22. However, the prices inclined slightly in the next quarter as the market demand rebounded. Given the limited inventories, the increased offtakes caused the sellers to raise their quotations averaging 1850 USD/MT ( CIF, USA) in December’22.

Analyst Insight

The price of acrylic will likely incline during the coming months owing to the renewed downstream demand. The increasing market enquiries along with stabilized logistics will cause the prices to rise.

Acrylic Acid Price Trend For the Second Quarter of 2022

Asia

Initially, the prices in Asia were higher as the factories were not running at optimum levels due to low market sentiments. However, this quarter saw a sharp decrease in acrylic acid prices for multiple reasons.

With the government easing covid restrictions, many industrial plants such as Yangtze INEOS and Celanese Nanjing restarted their manufacturing units and started churning more products in the market. This sudden change in the supply and demand dynamics led to massive stockpiling in the market, leading to prices falling. Acrylic acid market price tumbled from 14,786 RMB/MT in May 2022 to 13,939 RMB/MT (approx.) in June 2022.

Europe

Currently, the European market trend is the opposite of its Asian counterpart. Amidst the rising crude oil prices and inflated freight charges, the prices of almost all commodities are rising alarmingly.

The price of propylene, one of the primary feedstocks required for the chemical, reached around 1422 USD/MT FOB in Germany. The higher demand from the downstream sectors and the tightened supply of raw materials will likely inflate the price further.

Analyst Insight

According to Procurement Resource, the prices of acrylic acid will likely decrease in the coming quarter considering the current economic downturn. Despite the falling prices of feedstock propylene, the prices will fall as the muted market demand will lead to stockpiling of products in the market.

Acrylic Acid Price Trend For the First Quarter of 2022

Asia

In March 2022, per ton price of acrylic acid was 15000 RMB in China. Rising demand for superabsorbent polymers and broad adoption of acrylic-based goods in emerging economies such as Asia-Pacific propelled the acrylic acid industry.

Because of environmental concerns in countries such as North America and Europe, strict government restrictions on the usage of acrylic acid were enacted, acting as a significant restricting factor for the acrylic acid market's growth.

The rising demand for poly (methyl methacrylate) or PMMA resins in different sectors, as well as the commercialization of bio-based acrylic acid, were predicted to provide a lot of potential prospects for this industry. As a result, manufacturers concentrate on R&D to identify bio-based sources of acrylic acid.

Acrylic Acid Price Trend For the Fourth Quarter of 2021

Asia

Market activity in China fluctuated due to a variety of factors, the most notable of which was the abrupt emergence of a coal shortage in the country. The chemical rose to an extremely high value in a short period of time due to coal-related concerns, but eventually fell due to improved availability in the country.

Because of its reliance on China, the Indian market swung in a similar way. Despite strong offtakes from the domestic market, prices in the Indian market fell as well, despite the fact that they were already hanging at a very high figure. Finally, around the middle of November, acrylic acid price per ton was estimated to be around 2904 USD/MT.

Europe

The energy prices in the European market were soaring which was the primary reason of the rising commodity prices. The chemical’s price in Europe also followed a similar trajectory as other products supported by the sudden rebound of demand from the domestic market amidst limited availability and high cost of upstream.

As the prices rose consistently, the rates of downstream acrylates followed the same pricing dynamics while margins were shrinking every week in the domestic market. As the input cost witnessed an exorbitant hike in prices, the regional market trade activities did not help with the supply constraints.

North America

The effect of a manufacturing disruption caused by a winter storm in February was seen on the US market in this quarter as well. However, there was a significant increase in demand, with key downstream consumers reporting procurement issues.

Major manufacturers, on the other hand, significantly resumed their production activities after a long period of disruption. Another key issue for market participants were the increased upstream costs, which eventually resulted in significant inflationary pressure on downstream consumers. As a result, acrylic acid prices increased steadily in the United States throughout this quarter, reaching roughly 2200 USD/MT in October.

Acrylic Acid Price Trend For First, Second and Third Quarters of 2021

Asia

Acrylic acid and feedstock propylene faced a global shortage during the first quarter of 2021 which impacted its prices in the Asian market. Key manufacturers in Asia reported production constraints.

For example, the acrylic acid manufacturing unit of Tansee shut down in Saudi Arabia, Zhenjiang Satellite Petrochem plant in China witnessed a fire accident while South Korea’s LG chem plant too observed a prolong shut down. Propylene prices were skyrocketing at the same time which ultimately caused acrylic acid prices to rise from 1130 USD/MT in January to 1690 USD/MT in March 2021 in China.

In the second quarter of 2021, the market witnessed mixed sentiments as demand fundamentals varied among different countries. In India, the demand for the chemical was dull as the second wave of the coronavirus pandemic slumped demand for most downstream products.

In the first half of the second quarter, however, the prices rose as a result of high freight costs as it was majorly imported but declined later as trade activities improved across major Indian ports. In China, during the first half of second quarter, the chemical prices declined but rose again later as the feedstock prices witnessed an increment. In India, acrylic acid prices were around 1317 USD/MT whereas in China it was recorded at 1310 USD/MT somewhere around the middle of the second quarter.

Market prices witnessed a prominent rise during the third quarter of 2021 as the prices of feedstock propylene surged as a result of high crude oil prices. The feedstock availability was limited due to the production halt in several plants which was followed by a congestion in ports during July and August leading to a price rise of the chemical along with the factor of high demand from downstream sectors.

The monthly average FOB acrylic acid prices in September in Qingdao-China were 2357 USD/MT which had increased by 417 USD/MT since July. India, a major importer of acrylic acid, faced supply chain disruptions from Middle East and China as a result of port congestions and restrictions due to covid which also encouraged the price hike in the region during the third quarter. The monthly average acrylic acid prices Ex Mumbai in September observed a rise of 3.7% per MT since July, at 2455.99 USD/MT.

Europe

The market in Europe witnessed an acute shortage of the product while demand was high in the region during the first quarter of 2021. Supply shortages in various countries and regions were reported as a consequence of bad weather conditions as transportation was disrupted by the freezing cold weather while railway lines chocked due to frosts.

Moreover, a force majeure was announced by Evonik and Radici on their acrylic acid plants in Germany owing to the poor weather conditions. In Europe, the prices remained high in the second quarter backed by inadequate availability and firm demand across the region. Soaring high freight costs across Asia-Europe and US-Europe trade routes were also another major reason behind the price rise along with high feedstock prices in US as a result of winter storm in February.

Production activities resumed in several European countries as the economies recovered which increased the demand for acrylic acid in the region mainly from the downstream industries such as paints and coatings and adhesives. The market witnessed a firm demand amid limited supply during the third quarter which sent ripples in the market increasing the prices exponentially in Europe.

The hurricane Ida caused supply chain disruptions in the US while in China the Ningbo port shut down in August. Freight costs skyrocketed in major trade routes across Asia and US. All these factors encouraged the hike in the prices of the chemical. Additionally, the natural gas supply to Europe was disrupted for two months as Gazprom shut down its supply for maintenance purposes. High demand from downstream industries like adhesives and paints and coatings also drove up the prices during the third quarter.

North America

During the first quarter, the market witnessed a strong demand from downstream sectors amid low supplies which increased the prices in the region. Acrylic acid prices rose consistently from 1490 USD/MT in January to 1610 USD/MT in March 2021 as feedstock propylene faced shortage during this period as a result of freezing weather conditions across US Gulf coast which led to a global shortage of crude oil derivatives.

Meanwhile, demand from downstream sectors like constructional adhesive, packaging, coating remained high. The prices soared during the second quarter as upstream supply faced disruptions amidst a rising demand for the product. The US Gulf faced climate related issues which caused a major shortage of upstream products like n-butanol, ethyl hexanol and propylene.

The high prices of the chemical were backed by a strong demand from the downstream industries. Acrylic acid price increase was noted from 1690 USD/MT to 1770 USD/MT from April to June in the US. Additionally, the prices of several downstream products of acrylic acid increased during this period due to its supply shortage.

During the third quarter of 2021, the prices escalated amidst high demand and tight supply in the region. The feedstock propylene prices surged as a result of high crude oil prices which in turn affected the prices of acrylic acid and downstream products causing them to rise.

In addition to this, the disruptions caused by Hurricane Ida in the US during August, affected the production in several plants of acrylic acid and propylene, as well as also the supply chains in the overseas market.

For instance, by the end of August, Dow was forced to shut down the acrylic acid manufacturing plant as a result of power outages caused by the hurricane. Meanwhile an increase in demand from downstream industries like coatings and adhesives due to a growth in the construction sector also contributed to the factors in the price rise of the chemical in the region.

Acrylic Acid Price Trend For the Year 2020

Asia

In 2020, the market in Asia suffered due to weak global macroeconomics amid low demand from downstream sectors like adhesives, paints and coatings. Even though the industrial activities were recovering after the pandemic, they were affected by the resurgence of covid in several Asian countries which dampened the demand.

Scheduled turnarounds in Malaysia, Indonesia and Taiwan also curtailed the supplies. In India, the peak season was witnessed as the Diwali season approached. Butyl acrylate, a major trade grade in downstream acrylates, observed a downward trend since July 2020.

Europe

Some acrylate producers in Europe reported shutdowns for maintenance during the initial weeks of the third quarter which caused the domestic supply to tighten. Arkema, a leading producer, reported an increment in the prices of acrylic monomer in EU following the losses incurred in the last few quarters. The demand for downstream acrylonitrile-butadiene-styrene (ABS) increased and the margins rose. As buyer’s interest improved for ABS, the spot prices also registered double-digit increase by the end of the year.

North America

The market in North America witnessed a weak performance in around the third quarter of 2020 as the demand and supply fundamentals were hurt in US and Canada. Even though a slight gain in demand was reported from the adhesive, packaging and construction industries, the major acrylic acid producers observed little to no change in the quarterly numbers.

While the buying interests improved, the resurgence of coronavirus created a confusion among players. The pricing trend was pressured but improved in August as the gains of feedstock propylene extended.

Procurement Resource provides latest prices of Acrylic Acid. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customization of price currencies and unit; extraction of price data as excel files to be used offline.

About Acrylic Acid

Acrylic Acid is corrosive in liquid and vapour form, but it is an organic molecule. It is also, the simplest of the unsaturated acids. Many polymers are formed by Acrylic Acid, thus, making it a very useful raw material across several industries. It can be used to make plastics, detergents, paints, polishes, hygienic medical products, waste-water treatment chemicals, and others.

Acrylic Acid Product Details

| Report Features | Details |

| Product Name | Acrylic Acid |

| Industrial Uses | Resins, Adhesives, Oil treatment chemicals, Detergent , Water treatment, Water absorbent, Diapers, Textiles |

| Chemical Formula | C3H4O2 |

| Synonyms | 79-10-7, 2-Propenoic acid, Propenoic acid, Prop-2-enoic acid , Acroleic acid, Vinylformic Acid |

| Molecular Weight | 72.06g/mol |

| Supplier Database | The Dow Chemical Company, BASF SE, LG Chem Ltd. , Mitsubishi Chemical Corp., PJSC Sibur Holdings |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Acrylic Acid Production Processes

- Production of Acrylic Acid from Propylene via Oxidation

In this process, a starting reactant gas mixture which contains propylene, oxygen, and steam is passed through the first reactor containing molybdenum-based catalyst. The resulted gas is then passed through the second reactor in the presence of multi-component catalysts containing vanadium and molybdenum. The resulted gas out of this equation is Acrylic Acid, which is later collected in liquid form.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com