Product

Ethylene Glycol Price Trend and Forecast

Ethylene Glycol Price Trend and Forecast

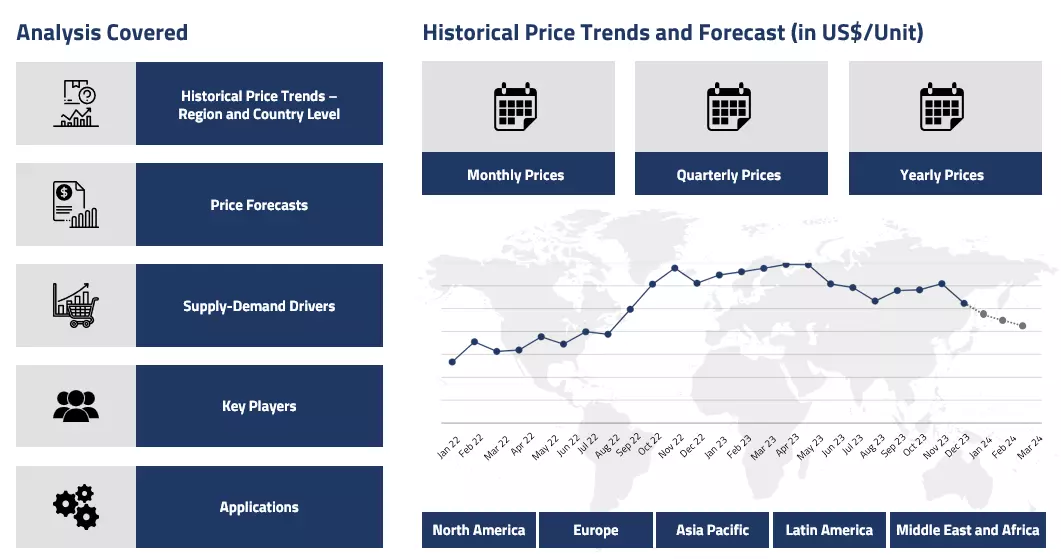

Ethylene Glycol Regional Price Overview

Get the latest insights on price movement and trend analysis of Ethylene Glycol in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Ethylene Glycol Price Trend for the First Half of 2025

Asia

During the first half of 2025, ethylene glycol prices in Asia experienced fluctuating movements. January saw a modest rise, supported by limited inventory and pre-Spring Festival procurement. However, this upward trend did not last long. As the holiday approached, trading activity weakened, and a cautious stance from downstream buyers led to softer demand.

Ethylene Glycol Price Chart

Please Login or Subscribe to Access the Ethylene Glycol Price Chart Data

After the holiday, increased port arrivals contributed to inventory accumulation, keeping pressure on prices. Through April, prices continued to slide due to flat polyester production and stable but low buying interest. Overall, the market remained oversupplied, and despite occasional supply tightness from plant maintenance, weak demand led to a generally declining price trend.

Europe

In Europe, ethylene glycol prices followed a largely bearish pattern in the first half of the year. The market faced weak consumption from key sectors like textiles and PET, while reduced feedstock costs further pushed prices down. March saw declining ethylene oxide prices due to lower ethylene input costs and destocking by traders, which also reflected in ethylene glycol trends.

Demand across the region was inconsistent—monoethylene glycol saw minor gains, but others like diethylene glycol underperformed. With limited seasonal demand triggers and oversupply conditions, price stability remained out of reach. Ongoing restructuring in the European chemical sector added to the uncertainty, further dampening price sentiment.

North America

In North America, ethylene glycol prices were similarly under pressure. Early in the year, production was briefly affected by weather disruptions in the Gulf region, but operations resumed quickly. The resulting inventory build-up added to supply-side concerns. Although demand from automotive and packaging sectors remained relatively stable, it wasn't strong enough to offset the oversupply.

In March and April, declining ethylene and ethylene oxide costs dragged glycol prices further down. Traders showed limited appetite for large-volume purchases, and spot transactions remained subdued. The market faced an imbalance between adequate supply and flat downstream demand, keeping prices on a downward path.

Analyst Insight

According to Procurement Resource, Ethylene Glycol prices are expected to remain range-bound with slight volatility unless demand from downstream sectors revives significantly or major supply adjustments occur.

Ethylene Glycol (EG) Price Trend for Q4 of 2024

Asia

In Asia, Ethylene Glycol prices declined throughout Q4’24. Demand from key downstream sectors like polyester and PET remained weak, which limited buying interest. Even though there were some production cuts and plant maintenance activities, inventory levels stayed high due to consistent domestic output and increased imports. Buyers were cautious, and overall procurement was minimal, which further dragged the market down. Stable feedstock costs and easing geopolitical concerns also contributed to a lack of strong price support, leading to a steady fall in prices across the region.

Europe

The European Ethylene Glycol market also saw a downward trend in Q4. Prices came under pressure early in the quarter as downstream demand remained soft, especially from packaging and textile applications. Supply remained steady, but weak economic sentiment and high inventories reduced purchasing activity. Falling upstream costs added to the negative momentum. Although some seasonal demand emerged in the last weeks of the quarter, logistical bottlenecks and concerns over transportation disruptions limited any potential rebound. As a result, the market closed the quarter on a low note.

North America

In North America, Ethylene Glycol prices moved higher during Q4’24. The market faced several supply-side issues, including production halts and weather-related disruptions, which reduced availability. Freight delays and logistical challenges further tightened the market. Meanwhile, upstream costs rose, driven by stronger crude and feedstock prices, adding pressure on production margins. Although demand stayed moderate, particularly from PET-related uses, reduced supply and higher costs created a firm pricing environment by the end of the quarter.

Analyst Insight

According to Procurement Resource, Ethylene Glycol prices may remain volatile, with supply conditions and downstream demand trends continuing to guide market direction in early 2025.

Ethylene Glycol Price Trend for Q3 of 2024

Asia

The Asian market showcased a mixed trend throughout Q3’24. The initial months witnessed price increases driven by seasonal demand peaks and robust consumption in the PET sector.

The market gained additional support from high cracker operating rates, particularly in South Korea. However, the anticipated restart of Vietnam's Longshan Petrochemical facility and increasing inventory levels eventually led to price corrections. The market experienced pressure from broader petrochemical sector weakness, though the tourism-related industries in China and Southeast Asia provided some demand support. By quarter-end, prices stabilized at lower levels due to balanced supply-demand dynamics.

Europe

The European ethylene glycol market demonstrated notable strength during the said period.The market gained support from multiple factors, including supply tightness and steady downstream demand. The closure of a key pipeline affecting Hungarian production due to sanctions on Russian supplier Lukoil created regional supply constraints, contributing to the price surge. The market also faced pressure from rising production costs and ongoing geopolitical tensions. Despite broader economic uncertainties, the consistent demand from key downstream sectors helped maintain the upward momentum, resulting in significant year-over-year price appreciation.

North America

The North American Ethylene Glycol (EG) market experienced a significant downward trend during Q3 2024, despite strong upstream ethylene prices. The market was primarily pressured by weak demand from the downstream PET sector and reduced consumption patterns. While Hurricane Beryl and facility outages impacted the upstream ethylene market positively, these supply disruptions couldn't support EG prices due to prevailing demand weakness. The declining trajectory was further amplified by inventory accumulation and sluggish buying interest from key end-use industries. The Mexican market particularly reflected this bearish sentiment, though prices remained elevated compared to previous periods, indicating the complex market dynamics at play.

Analyst Insight

According to Procurement Resource, the Ethylene Glycol market is expected to face continued pressure in the short term, particularly in regions with weak downstream demand. While supply-side constraints may provide temporary support, the overall market sentiment remains bearish due to economic uncertainties and potential demand slowdown.

Ethylene Glycol Price Trend for the First Half of 2024

| Product | Category | Region | Price | Time Period |

| Ethylene Glycol | Chemicals | China | 629 USD/MT | January’24 |

| Ethylene Glycol | Chemicals | China | 625 USD/MT | June’24 |

| Ethylene Glycol | Chemicals | India | 746 USD/MT | January’24 |

| Ethylene Glycol | Chemicals | India | 837 USD/MT | June’24 |

Stay updated with the latest Ethylene Glycol prices, historical data, and tailored regional analysis

Asia

The ethylene glycol market observed a very mixed price trajectory in the Asian markets during the first half of the year 2024. During the first half a rise in crude oil prices and the feedstock ethylene oxide prices pushed the market trajectory uphill in both Indian and the Chinese markets. The downstream demands from the adhesive and polymer industries were also supporting the prices. However, as the second quarter arrived, there was a downturn in crude oil prices, which started influencing the ethylene glycol prices as well.

The Chinese ethylene glycol market was relatively more consolidated compared to the Indian ethylene glycol market. In the Chinese ethylene glycol market, the monthly average prices went from about 629 USD/MT in January’24 to about 625 USD/MT in June’24. On the other hand, the Indian ethylene glycol markets saw the prices go from about 746 USD/MT in January’24 to around 837 USD/MT in June’24. Overall, a positive price-performance was witnessed during the said span.

Europe

In the first half of 2024, European chemical and resin markets witnessed great variations in prices. In the first quarter, the upstream outlook was supportive with a high-cost drive influenced by the inclination in crude oil costs. However, in the second quarter, crude oil prices started normalizing gradually. OPEC member countries sustained their decisions to keep the production outcomes restricted to balance the crude oil markets globally. Overall, mixed market sentiments were witnessed for ethylene glycol in the first half of 2024.

North America

In the first half, the American ethylene Glycol market witnessed a steady and confined momentum in prices driven by supply-demand imbalances, increased production costs, and rising trading uncertainties. In the US, ethylene glycol prices surged by a noticeable margin as compared to Q4 of 2023 as the cost of its feedstock inclined by several folds. With the rising geopolitical tensions, notably the escalated tensions in the Middle East with Israel and Hamas war heating up, the supply chains got complicated.

Ukrainian drone attacks on Russian refining facilities exacerbated issues in the crude oil market, further affected by the Red Sea crisis. All these factors kept the ethylene glycol markets inclined during Q1’24. However, a slight normalization of production costs changed the market direction in the second quarter as the price graph started flattening up following the prices.

Analyst Insight

According to Procurement Resource, the price of Ethylene Glycol is estimated to further fluctuate with the variation in the prices of feedstock ethylene and persistent challenges in the global supply and demand trends of the different regions.

Ethylene Glycol Price Trend for the Second Half of 2023

| Product | Category | Region | Price | Time Period |

| Ethylene Glycol | Chemicals | India | 490 USD/MT | July’23 |

| Ethylene Glycol | Chemicals | India | 722 USD/MT | December’23 |

| Ethylene Glycol | Chemicals | China | 560 USD/MT | July’23 |

| Ethylene Glycol | Chemicals | China | 589 USD/MT | December’23 |

Stay updated with the latest Ethylene Glycol prices, historical data, and tailored regional analysis

Asia

The ethylene glycol industry fared well in the Asian region throughout the given period of H2’23. Its robust demand from the automobile and polymer sectors drove the prices uphill for the entire duration. The Indian market saw a relatively more inclined price graph than the Chinese ethylene glycol markets.

In the Indian market, the monthly average prices showed an excellent approximate growth of more than 40% as the prices stood at an average of about 490 USD/MT (India, CIF) in July’23 and then jumped to around 722 USD/MT (CIF) in December’23. The Chinese market also grew during this time; however, the growth here was comparatively more confined as the monthly average spot prices went from about 560 USD/MT in July’23 to about 589 USD/MT in December’23, rendering a growth of about 5% in the Chinese market.

Europe

In the European ethylene glycol markets, the price trend was observed to be closely following the market behavior of its feedstock material, ethylene oxide, throughout the said period. Mimicking this the ethylene glycol price graph traversed differently through both the concerned quarters. During quarter three the prices were more inclined as the market demands were high and upstream costs were also surging. However, as quarter four hit, the prices turned down with a swift fall in the production charges along with a fallen demand outlook.

North America

The North American ethylene glycol market strongly reflected the market run of its European counterparts, as the prices were observed to be fluctuating here as well. After rising throughout the third quarter, the ethylene glycol prices in the American markets fell consistently in the fourth quarter. This oscillation was also influenced by the changes happening in the crude oil prices during this time. Freight issues of the year-ending months curbed the industrial demands in the later phase of Q4.

Analyst Insight

According to Procurement Resource, Ethylene Glycol price trends are expected to continue fluctuating in the coming months as well. The current supply outlook does not suggest much change in the global price trajectory going forward.

Ethylene Glycol Price Trend for the First Half of 2023

Asia

The Ethylene Glycol price trend fluctuated throughout the first half of 2023. The prices tried to stabilize as the market was in a slump for a long time, but the situation didn't improve; Ethylene Glycol prices again turned south after rising in February. Overall, market sentiment was of depreciation as in the Chinese domestic market, Ethylene Glycol began with an average price of about 610 USD/MT (Spot FD) in January '23 and closed the second quarter at around 566 USD/MT (Spot FD) with an average declination of about 7%. Sluggish demands from the downstream industries kept the market sentiments dull.

Similarly, in the Indian domestic market, Ethylene Glycol prices oscillated throughout, but some upward fluctuations were observed at the quarter shift, with prices averaging as high as about 570 USD/MT (CIF, India) around March and stooping as low as about 495 USD/MT (CIF, India) in June 2023. Overall, the market exhibited mixed behavior with dull sentiments.

Europe

In the European Ethylene Glycol market, the prices showcased a stable but declining pattern during the said period. High inventories with steady demands were the primary reason behind such market performance. In the German domestic market, the average prices started from about 943 USD/MT (CIF, Germany) and closed the second quarter at around 931 USD/MT (CIF, Germany). Overall, the market fluctuated within a narrow range throughout the said period.

North America

In the North American market, the price trend of Ethylene Glycol exhibited a similar behavior to the European market. The market tried to stay firm and strong at the beginning of the first quarter, but the trend couldn't sustain and turned south soon in the second half of Q1. Overall, a dull market sentiment was observed.

Analyst Insight

According to Procurement Resource, the Ethylene Glycol market is expected to exhibit similar price trend in the upcoming months since the driving fundamentals appear unchanging.

Ethylene Glycol Price Trend for the Second Half of 2022

Asia Pacific

Since the beginning of the third quarter, the Asian-Pacific region saw a sluggish demand for ethylene glycol. China, one of the significant importers of ethylene glycol, witnessed fewer inquiries from the end-user industries. The downturn in China’s economic conditions was one of the major causes of this decline. The shadows of virus outbreaks and low consumer demand led to the negative fall of the market. Major Chinese ports also witnessed the accumulation of stocks despite the steady supply of the material.

Europe

In the European region, many manufacturers reduced their operating rates due to the low demand and unstable natural gas prices, thereby heavily impacting the ethylene glycol prices. Consumer confidence also fluctuated due to inflation as a result of high energy costs, shrinking profit margins, and declining demand. Additionally, the weak economic conditions in the European region decreased buying potential of consumers and led to the declining price trend of ethylene glycol.

North America

The region’s weak demand brought attention to the massive inventory build-up and kept export and local pricing under pressure. In the North American region, delays in cargo imports and exports were brought on by port closers and restricted port operation hours. The hurricane conditions further prolonged the shipping delays. The region also saw labour disagreements and a scarcity of storage spaces. All these factors contributed to the downward trajectory of ethylene glycol prices.

Analyst Insight

The prices of Ethylene Glycol are expected to increase in the upcoming months. The limited availability of material and the rise in operation from the downstream industries will lead to an incline in the prices.

Ethylene Glycol Price Trend For Second Quarter of 2022

Asia

In the Chinese domestic market, ethylene glycol prices tipped towards the lower side. The falling prices of feedstock ethylene, sluggish demands from the downstream polyester and polyethene sectors, and the rising global recession speculations caused a massive dip in the price trend of ethylene glycol. Per ton price of ethylene glycol averaged 712 USD FOB Shanghai in the said quarter.

Europe

In contrast with the Asian market, ethylene glycol prices constantly rose in the European market. The volatile prices of crude oil caused the petrochemicals prices to rise. With the tightened supply, the rising demands from the polyester and filaments sectors further aggravated the case. This supply-demand mismatch caused the prices to inflate in the domestic market averaging CFR 1108 USD/MT Hamburg.

North America

The ethylene glycol market witnessed unprecedented volatility in the US domestic market. The soaring prices of feedstock petrochemicals and increasing demand from the end-user industries caused the prices to inflate. With the upstream sectors struggling to keep up with the market demands, ethylene prices averaged FOB 868 USD/MT US Gulf.

Analyst Insight

According to Procurement Resource, ethylene glycol prices are expected to decline in the coming months. Given the current cautious wait-and-see attitude of the buyers owing to the looming speculations of a global recession will likely cause the prices to fall.

Ethylene Glycol Price Trend For First Quarter of 2022

Asia

The average price of oil-based ethylene glycol in China on March 31st was 5,200 RMB/MT, up 33.33 RMB/MT from the previous data cycle. In March 2022, ethylene glycol prices increased initially, then declined. The overall international crude oil was strong, corresponding to high naphtha and ethylene prices. Many terminals were too high after the increase in the first half of this month. The chemical's cost was under pressure to follow the increase in the second half of this month, but the rise was held back by sluggish demand.

North America

The chemical company Eastman announced a price increase of 0.12 USD/lb for the chemical in March.

Ethylene Glycol Price Trend For Fourth Quarter of 2021

Asia

Increased exports from Saudi Arabia into the Indian domestic market, along with high inventory levels, resulted in an oversupply, which deteriorated market volatility in October. In H2 of Q4, lukewarm demand from downstream textiles exacerbated market pessimism. Ethylene glycol prices declined from 74910 INR/MT in October to 59620 INR/MT in December on an ex-location basis. In China, a lack of demand support and a decline in feedstock prices in the face of dropping crude and coal prices contributed to a depressed market mood during Q4 of 2021. On a FOB basis, the chemical's prices decreased from 1000 USD/MT in October to 841 USD/MT in December.

North America

The North American region's market attitude remained constant, as abundant production and slow demand from the downstream polyester sector-maintained market rangebound throughout the quarter. Prices of feedstock ethylene stabilised following a period of high volatility in Q3, as upstream natural gas prices stabilised since crossing USD 5 per MMBTU in October. Prices surged in October, reaching 837 USD/MT FOB; however, demand decreased in Q4's H2 period, resulting in a price reduction to 683 USD/MT in December.

Europe

Natural gas prices continued to rise, putting upward pressure on the cost of feedstock ethylene, which raised the cost of producing the chemical during the last quarter. Demand from secondary polyester and PET producers remained high in the fourth quarter, prompting market participants to maintain strong pricing for accessible in European markets. On a forward contract basis, the price jumped from 850 USD/MT in October to 970 USD/MT in early December. Shipping of the chemical from Asia to Europe remained sluggish as well, owing to high freight costs along the Mediterranean route.

Ethylene Glycol For First, Second and Third Quarters of 2021

North America

North American production was halted as a result of the US gulf storm, which shut down over 68% of the US's output. Several major plants, including Indorama Ventures, Lotte Chemicals, Ethylene Glycol Global, and a few others with a combined annual production of 1,850,000 MT, were shut down due to the freezing storm. These shutdowns resulted in a regional scarcity of the chemical and a global shortage. Thus, ethylene glycol prices moved in lockstep which lingered around 1155 USD/MT in February 2021. Later in March, as US production resumed, the prices slowed.

Prices increased steadily throughout the quarter in the North America region, supported by increased demand from the downstream sector, while availability remained insufficient to meet the overall needs of the regional market in the USA. Major manufacturers attempted to increase plant utilisation rates, which had been low due to adverse weather circumstances in the previous quarter.

Additionally, Lotte Chemicals experienced an unforeseen plant shutdown in May due to a technical issue at their Louisiana facility. Meanwhile, overall supply operations in the United States were constrained during the quarter, while demand from downstream PET makers remained strong. As a result, ethylene glycol prices in the United States increased from 1364 USD/MT to 1440 USD/MT between April and June.

The price of the chemical experienced a significant increase in Q3 2021. By the end of August, numerous manufacturers were obliged to close their factories for about two weeks in advance of the Ida hurricane in the US Gulf Coast, as part of a contingency plan that resulted in a decline in the region's ethylene glycol production rates.

Major ethylene producers in Louisiana, including as Dow, Taft, and Shell, also placed a turnaround on their production plants, impeding the manufacturing of the chemical. Additionally, throughout the quarter, demand from PET makers remained strong. As a result of the tight supply and high demand, prices increased during the Q3. In September, US Gulf MEG prices settled at 870 USD/MT.

Asia

Demand remained strong across Asia, while supply remained constrained, supporting its prices. Reduced output and decreased imports from the United States, as well as premium imports from European countries, all contributed significantly to an increase in ethylene glycol prices across the region.

Plants such as Sanjiang Fine Chemicals, having an annual capacity of around 380,000 MT of ethylene glycol, declared a maintenance turnaround, while Far Eastern Union Petrochemical Ltd., having an annual capacity of 500,000 MT, also reduced its production capacities from 100% to 90% to protect margins. Additionally, due to the fact that some factories ceased production during the Chinese lunar holidays, which lowered their inventory, the average price throughout Asia jumped by more than 12% following the Lunar holidays. However, in India, prices increased 35.17% from January to conclude the quarter at 814.47 USD/MT.

During quarter 2, the demand varied by country in Asia. In China, domestic demand for remained modest to firm from downstream PET makers, despite enough supply to meet their domestic demands. Additionally, large Chinese manufacturers booked massive shipments for Europe in the interim.

While the Indian market battled with low costs as a result of the country's pandemic effect, after reaching a low point, prices continued to fluctuate throughout June as a result of low adequate stock availability and variable demand from the domestic and international markets. Thus, following a few oscillations, prices in India stabilized at 745 USD/MT in the final week of June.

Prices of the chemical increased in the Asian markets in Q3 2021, owing to limited supplies and strong demand from downstream PET and Polyester film makers. In China, the market experienced a price increase due to congestion at numerous Chinese ports and lower production volumes in the latter half of the quarter, exacerbated by the energy crisis.

In India, prices increased as a result of the spillover effect from China's shipments to Europe, as well as the increasing feedstock values as a result of the enormous surge in crude oil prices. Additionally, the increase in offtakes from downstream sectors had an effect on the price. Price for Ex-Kandla was recorded at 823.44 USD/MT in September, indicating a little increase since July.

Europe

Europe had a chance to address supply gaps caused by the US market in the aftermath of February's winter storm interruption, which impacted overall Central American production. Following the hurricane that struck the US Gulf Coast, export demand on industry players increased significantly, primarily from Asian countries. Additionally, rising freight and container costs impacted upstream ethylene pricing, which ultimately resulted in an increase in ethylene glycol prices across the region.

During the second quarter, Europe experienced strong demand for the chemical. Europe imposed anti-dumping duties on Middle Eastern manufacturers in May, allowing Asian manufacturers to ship their wares to European clients. As a result, a huge proportion of cargo was also scheduled by Chinese manufacturers to meet total demand. Additionally, European countries faced high freight costs, which compounded the region's overall situation for the chemical.

In the EU market, the third quarter saw a slight increase in its price. Delayed imports from Asia due to congestion in China's ports, along with a container scarcity, contributed to the increase in the cost pattern in Europe. Additionally, high freight costs and strong demand impacted the price in the third quarter. In September, prices were estimated at 970 USD/MT.

Ethylene Glycol Price Trend For the Year 2020

Asia

The Asian market reached a record high in 2020, owing to robust polyester demand and a tightening of cargo inflows from the US. Prices reached a near six-month high after many production cuts were made due to a wide ethylene glycol-naphtha spread. As the United States is the largest exporter of the chemical to Asia, repeated plant shutdowns in the aftermath of Hurricane Laura worsened this supply shortage. However, as new plants became operational in China during the year, sufficient production was seen.

North America

With the automotive industry reviving its market dynamics following a severe blow from the pandemic and lockdowns, demand increased significantly in the third quarter of 2020. However, the production cuts undertaken at several factories across the country in preparation of Hurricane Laura significantly reduced the region's export potential, resulting in lower revenues in comparison to the previous quarter. Traders were confident about increasing purchasing activity from eastern countries as they stockpiled items to alleviate supply shortages caused by China's October National Day vacation.

Europe

According to European Commission forecasts, the value of ethylene glycol manufacturing was estimated to be around 318.3 million Euros in 2020. Throughout the period under examination, the value of production had decreased. Despite Asia's bullishness, prices spiraled downwards. Contract pricing was on track for a double settlement in August 2020 and was likely to occur concurrently with a September 2020 first settlement.

Procurement Resource provides latest prices of Ethylene Glycol . Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Ethylene Glycol

Ethylene Glycol appears as a clear, colourless syrupy liquid having the ability to absorb water. It is odourless but comes with a sweet taste. The chemical is utilised to make antifreeze as well as de-icing solutions for cars, airplanes, or boats. It is also utilised in hydraulic brake fluids as well as in inks that are utilised in stamp pads, ballpoint pens, or print shops.

Ethylene Glycol Product Details

| Report Features | Details |

| Product Name | Ethylene Glycol |

| Industrial Uses | Adhesives and sealant chemicals, Coolant and heat-transfer agent, Antifreeze formulations, Precursor to polymers, Dehydrating agent, Air-conditioning |

| Chemical Formula | (CH2OH)2 |

| Synonyms | 107-21-1, 1,2-ethanediol, Ethylene alcohol, Hypodicarbonous acid, Monoethylene glycol, 1,2-Dihydroxyethane, Ethane-1,2-diol |

| Molecular Weight | 62.07 g/mol |

| Supplier Database | ME Global, Saudi Basic Industries Corporation (SABIC), China Petroleum & Chemical Corporation (Sinopec), Reliance Industries Limited, Shell Global, INEOS Capital Limited, India Glycols Ltd., SPDC Ltd. |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Ethylene Glycol Production Processes

- Production of Ethylene Glycol via Hydrolysis of Ethylene Oxide

In this process, hydrolysis of ethylene oxide with water forms a coarse ethylene glycol combination. Further, vacuum fractional distillation is carried out to separate oligomers such as monoethylene and triethylene glycol along with water to obtain Ethylene Glycol as the result.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Related News

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com