Product

Lead Ingot Price Trend and Forecast

Lead Ingot Price Trend and Forecast

Lead Ingot Regional Price Overview

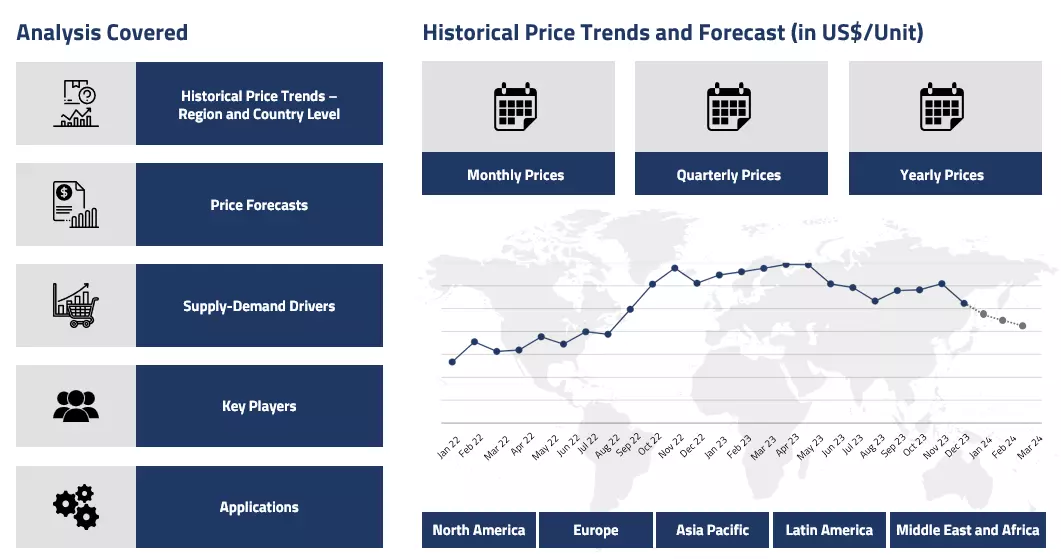

Get the latest insights on price movement and trend analysis of Lead Ingot in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Lead Ingot Price Trend for the Second Half of 2024

In H2'24, the prices of lead ingots in the global markets followed an oscillating trajectory, displaying month-on-month fluctuations. At the start of the quarter, prices continued their downward trend from the previous period, influenced by weak demand in the broader metal market. This initial decline reflected a cautious approach from traders who adopted a wait-and-see attitude in anticipation of potential government policy changes. However, after the announcement of U.S. Federal Reserve cuts, the market showed a gradual upward movement, leading to a steady rise in prices.

Lead Ingot Price Chart

Please Login or Subscribe to Access the Lead Ingot Price Chart Data

Meanwhile, in China, the government introduced economic stimulus measures to support its domestic metal market. The country's shift towards protectionist policies impacted market dynamics, with further implications expected in the next financial year. However, during the said period, the stimulus measures provided short-term support, stabilizing the market in the second half of H2'24.

Analyst Insight

According to Procurement Resource, the prices of Lead Ingot are expected to show a fluctuating trajectory influenced by trade policies and supply disruptions in the upcoming months.

Lead Ingot Price Trend for the First Half of 2024

In the first half of 2024, lead ingot prices in China experienced an upward trend, driven by a significant reduction in both primary and secondary domestic production and a sharp decline in lead concentrate imports. The tighter market conditions were further exacerbated by the lower availability of refined lead metal and a substantial drop in net exports, leading to increased prices. Across the rest of Asia, the market dynamics were mixed, with countries like Japan and South Korea seeing higher usage of refined lead metal, while regions such as Thailand faced reduced demand.

In contrast, the European market faced downward pressure on lead ingot prices due to reduced consumption in key sectors, particularly automotive and batteries, despite some production increases in Bulgaria and Italy. In North America, lead prices followed a similar downward trajectory, influenced by slowing demand in the U.S. automotive battery sector, although Mexico showed some resilience with a slight year-on-year increase in demand. Overall, the global lead ingot market in H1 2024 was marked by regionally varied trends, with supply constraints driving prices up in some areas while demand reductions pushed prices down in others.

Analyst Insight

According to Procurement Resource, the market trajectory for Lead Ingot is likely to change as the prices are expected to take a southward route moving forward. Inventory destocking is likely to exert downward pressure on the lead ingot prices in the coming months.

Lead Ingot Price Trend for the Second Half of 2023

Lead ingots are primarily utilized in the manufacturing of lead-acid batteries, constituting a significant portion of global lead consumption. Additionally, lead ingots find application in the production of lead oxide, lead alloys, lead salts, and cables.

Their malleability, corrosion resistance, and high density make them indispensable in industries such as construction, automotive, electronics, and plumbing. Moreover, lead ingots play a crucial role in radiation shielding and as a component in ammunition and soldering materials, and thus, the above-mentioned industries have a significant influence on the price trend of lead ingots.

The lead ingot market was influenced by various factors, including downstream applications, production levels, and global supply-demand dynamics during the third and fourth. In China, lead consumption is primarily driven by lead-acid batteries, which account for over 80% of its usage. Despite fluctuations, China has seen a steady increase in lead-acid battery production supporting the demand for lead ingots domestically. Along similar lines, China's lead production has surged, indicating a positive momentum in the market.

On a global scale, lead ingot production struggled to meet demand, as evidenced by supply shortages reported by the World Bureau of Metals Statistics. The manufacturers started to ramp up their operation rates after their maintenance shutdowns to balance out the supply and demand of the markets. However, significant price shifts in the major economies of the world were influenced by macro-level factors and shifting demand patterns.

Analyst Insight

According to Procurement Resource, the price of Lead Ingot is estimated to incline amid the growing trade challenges and disruption of major sea routes along with rising concerns regarding the ongoing geopolitical tensions.

Lead Ingot Price Trend for the First Half of 2023

The price trend of lead ingot suffered drastically in the first quarter of 2023, while the second quarter was much more stable as compared to the first. The second quarter was supported by the demand from some major regions, such as Europe and the US, giving strength to the export rates of China. Chinese output of lead ingots increased as compared to the previous quarter as the smelters, both secondary and primary, restarted in the region.

The rates of exports from China were at an all-time high since 2021 in the second quarter. Despite the challenging conditions in China, both economic and operational, the rates of production were not much affected. In addition to this, the demand from Europe struggled due to the weak movement of the economy and technical recession observed in several countries.

Analyst Insight

According to Procurement Resource, in the second half of 2023, lead ingot prices are expected to stay constant as China's exports of refined lead ingots offset sluggish output in the major demand areas.

Lead Ingots Price Trend for the Second Half of 2022

The prices of lead ingots in the third and fourth quarters showcased a bullish trend as during this time, the automotive sector, which is one of the major consumers of this metal, showed less interest in the market. The primary cause of this lack of interest was a constriction in production rates due to a lack of demand from consumers. As a result, the production of lead ingots also got reduced to keep the levels of rising inventories in check.

Since Russia's invasion of Ukraine in February, the outlook for lead demand has progressively been worse, and the declining trajectory continued till the end of the year. Because of supply-side disruptions at automotive plants, production was weak, which resulted in a low demand for refined lead. Sales of lead ingots also suffered as a result of rising interest rates and skyrocketing energy costs.

Analyst Insight

According to Procurement Resource, the price of Lead Ingots is expected to showcase stagnancy as the rates of supply seem to be improving along with the market conditions of the automotive sector.

Lead Ingot Price Trend For the First Quarter of 2022

Asia

Lead ingot prices were around 15,408 RMB/MT in the first half of January 2022 following a fall in prices by the end of the month. In February, the market in China was mostly weak with prices dropping to as low as 14,928 RMB/MT. In the beginning of March, the price in the domestic market of China stood at around 15,350-15,450 RMB/MT which increased to 15,600 RMB/MT by the end of Q1 2022.

Lead Ingot Price Trend For the Fourth Quarter of 2021

Asia

Refined lead prices rose over 4% in the final week of December as stockpiles fell, but the metal's prices had already reached their top. According to SMM Consulting in China, several smelters were performing maintenance operations, resulting in lower ingot inventories.

Lead ingot prices rose as a result, but now with secondary smelters restarting operations, prices may be put under pressure. Lead for shipment in January was estimated 50 RMB (7.83 USD) higher on the Shanghai Futures Exchange at 15,380 RMB/MT (2,409 USD). Lead ingot prices are expected to stabilise in the current and coming quarters.

As disruptions are projected to end throughout these two quarters, supply shortages should end. In December 2021, markets were well-supplied, with China continuing to increase shipments to countries like the United States, who were experiencing shortages or concerns like as high transportation costs.

Europe

Metal production was hampered by a lack of electricity and expensive expenses in Europe, which drove up LME lead prices and compensated for losses during the Chinese New Year break. For a week, Europe's power supply was short, while LME supplies remained stable, despite China's planned lead ingot exports to Europe. In the month, the LME price remained stable at 2,300 USD/MT.

North America

The rapid increase in its inventories in China was fueled by ambitious development of secondary lead capacity and substantial tolling activity at Chinese smelters. Warehouse stocks on the Shanghai Futures Exchange reached new highs this year, surpassing 200,000 MT. High shipping rates and container restrictions kept the surplus in China at a time when increased price fluctuation and smelter outages caused shortages abroad.

Physical premiums in the United States surged to multi-year highs, while supplies in the LME warehouse network fell to 12-year lows. After the slight surplus that built in China this year, the refined lead market dynamics will progressively rebalance during 2022, according to the global supply-demand model.

This rebalancing is based on forecasts of increased demand from the automotive business (which has been harmed by a semiconductor shortfall that has prompted automakers to restrict production) and the freight and transportation industry loosening up.

Lead Ingot Price Trend For First, Second and Third Quarters of 2021

Asia

In September, China shipped 15,545 MT of refined lead, the highest volume (shipment) since 2007. The Shanghai Futures Exchange (ShFE) had three times the global warehouse inventories of the metal indicating that Beijing could export further lead during the year. In 2018, inventories hit a new high, putting a lot of pressure on the supply side.

However, stocks of final products at battery manufacturers continued to rise in 2021 as delivery sources dried up, and consumption slowed during the off-season. Purchases were made at low prices by downstream users. As the TCs continued to plummet, primary smelters of the metal profited most from byproducts. Jinli was being serviced, but the output was unaffected. As Henan Yuguang's production resumed, and overall output grew. In May 2021, the price difference between primary and secondary metal was noted in the range of 200 and 300 RMB/MT.

Europe

In Europe, there has been an upsurge in the use of lead. Prices in the international market had risen by more than 7% since the beginning of the year, but they fell by the end of the year as supplies improved. Increased recycling of automobile batteries enhanced secondary production of the metal or recycling in the second half of 2021.

The metal had earlier been overlooked and was falling behind. Prices in Germany soared to a three-year high in September 2021 when a major lead smelter was forced to close due to flooding. Berzelius Stolberg, Europe's largest primary smelter, announced force majeure on metal supplies from its facility in western Germany. After topping 2,350 USD/MT, the strongest since July 2018, the three-month leads on the London Metal Exchange had risen 0.3 % to 2,336 USD/MT.

North America

Although the United States accounts for 13% of the world demand for the metal, the termination of COVID-19 lockdowns raised its consumption as motorists sought substitutes for lead-acid batteries that had failed after long periods of inactivity. The metal had a solid year, prompting the company to raise its price expectation for the year to 2,200 USD/MT from 2,125 USD/MT, with the metal averaging 2,316 USD/MT in November and December.

Over the next few months, the rising vehicle prices began to have an influence on the recovery in global automobile production, halting the rise in its consumption. There were projections that demand growth would outpace production growth this year, reducing the annual production surplus. Supply was short in the United States due to a lack of imports, logistical issues, and port congestion, while demand was high following the restoration of the economy following the Covid-19 lockdowns.

Lead Ingot Price Trend For the Year 2020

Asia

Domestic lead scrap and ingot prices in India increased by 1-3% in August 2020, because of increased output in the car sector, which drove the demand for new batteries. Domestic lead ingot prices were also supported by a 3% increase in formal three-month LME lead prices to 1,981 USD/MT. To accommodate the rising demand from the car sector, smelters in Mumbai and Delhi boosted output. During India's forthcoming Christmas season, automakers predicted pent-up demand.

With demand on the horizon, smelters were steadily upping bids, resulting in a price increase of 3,000-4,000 INR/MT in Cities like Mumbai and Delhi. Prices of re-melted and purified lead had been climbing since mid-July, putting ingot makers in a great place. Because the price gap between imported and domestic lead ingot is so small, cornering a profit from imported lead ingot became impossible.

This resulted in a surge in demand for indigenous ingots, owing to the government's emphasis on self-reliance, known as 'Atmanirbhar Bharat.' Following the lockdown, several importers reduced their imports.

North America

After Doe Run shuttered its smelter in Herculaneum, Missouri, in 2013 and Glencore dismantled its Brunswick smelter in Canada in late 2019, the US lead market tightened. Labor constraints, general material scarcity, transportation constraints, and the high cost of freight overseas increased the tightness during and after the Covid-19 outbreak. Premiums remained high as a result of these factors.

The spike in raw material prices emerged at a time when the lead and battery supply chain was struggling to replenish automotive lead battery stockpiles in various regions of the world. Despite stricter environmental restrictions, the usage of refined lead in the worldwide automotive sector continued to expand in the United States. Despite the fact that the use of lithium batteries is increasing as more electric vehicles are produced, the restricted availability of lithium has forced battery producers to rely on lead batteries for the next decade.

South America

In 2021, most metal smelters were operating at high output rates, fueled by ample feed and increased scrap flows. Concentrate availability had been restricted, primarily due to virus-related mining closures.

Procurement Resource provides latest prices of Lead Ingot. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Lead Ingot

In general, ingot refers to a piece of relatively pure substance, often a metal, that is cast into a shape ideal for further processing. Lead Ingot is a silvery white lead product produced from a secondary procedure of shaping, such as cold/hot working, cutting, or milling. Lead Ingots are available in various sizes ranging from 10 LB ice cube tray ingots to 70 LB large ingots, with dross-free and smooth top surface. They are useful in general applications as ingots are generally the least costly form of metallic products.

Lead Ingot Product Details

| Report Features | Details |

| Product Name | Lead Ingot |

| Industrial Uses | For radiation shielding, Ballast, Counterweights, Building construction material, Ammunition, Lead acid battery, Lead products (sheet, pipes, wire, etc.), Lead oxides and chemicals, Pigments, Cable sheathing, Aerospace, Ship building, Re-melt for industrial applications |

| Chemical Formula | Pb |

| Synonyms | 7439-92-1, Lead pigs, Bullion or bar lead |

| Molecular Weight | 207.2g/mol |

| Supplier Database | Mars Metal Company, American Elements, Pilot Industries Limited, Gravita India Ltd, Jayachandran Alloys (P) Ltd |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Lead Ingot Production Processes

- Production of Lead Ingot via Pyro Metallurgical Process

Lead Ingots are produced from lead scraps/ raw lead bullions/ remelted or secondary lead ingots through pyro metallurgical process. In this process, thermal treatment of minerals and metallurgical ores and concentrates is carried out to bring about physical and chemical modifications in the materials to recover Lead Ingot. After thermal treatment, the obtained molten lead is mixed with alloys, including antimony, tin, etc. and finally casted into ingots.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Related News

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com