Product

MCA (Monochloroacetic Acid) Price Trend and Forecast

MCA (Monochloroacetic Acid) Price Trend and Forecast

Monochloroacetic Acid Regional Price Overview

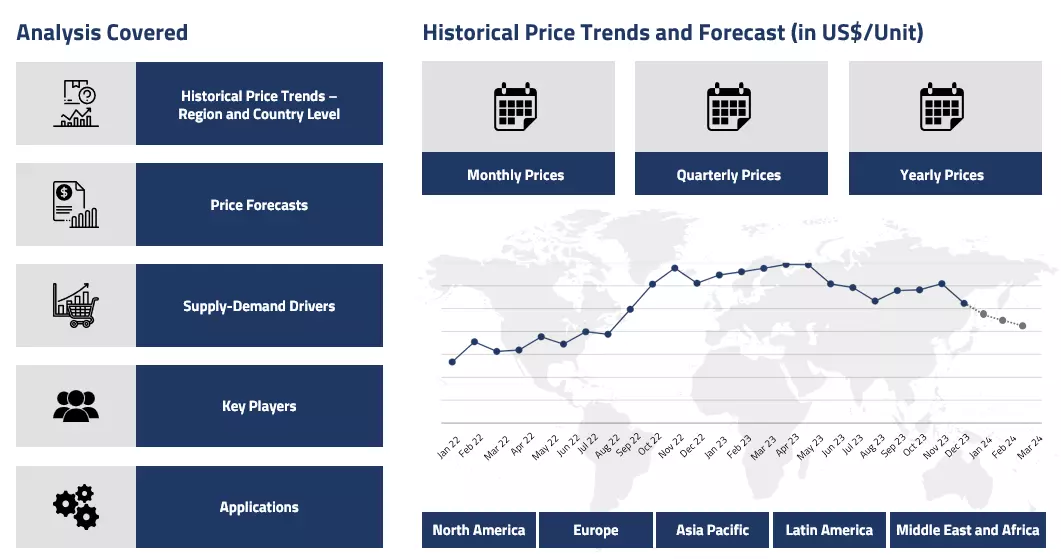

Get the latest insights on price movement and trend analysis of MCA (Monochloroacetic Acid) in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Monochloroacetic Acid Price Trend for the Q4 of 2024

Asia

In Asia, Monochloroacetic Acid prices followed a moderate upward trend during Q4'24. The market was primarily influenced by rising feedstock acetic acid costs and supply constraints from major producing regions. Chinese exports remained steady but at elevated levels, which affected pricing across the region.

Monochloroacetic Acid Price Chart

Please Login or Subscribe to Access the Monochloroacetic Acid Price Chart Data

The downstream textile sector showed mixed performance, with demand varying across different countries. The carboxymethyl cellulose (CMC) industry, a key consumer of Monochloroacetic Acid, maintained stable consumption levels throughout the quarter, providing some support to the market.

Europe

The European Monochloroacetic Acid market experienced price fluctuations throughout Q4'24. Germany and the Netherlands, key markets in the region, faced pressure from expensive Asian imports. Producer prices showed marginal improvements, though industrial activity remained subdued. The downstream textile sector's performance was particularly weak, with reduced demand affecting market dynamics. Manufacturing costs increased due to ongoing energy concerns, while feedstock Acetic Acid prices remained volatile. The non-food sector showed minimal growth, impacting the overall demand for Monochloroacetic Acid in various applications.

North America

In North America, particularly the US, Monochloroacetic Acid prices-maintained stability with a slight downward tendency during Q4'24. The market was significantly influenced by changing patterns in the agricultural sector, where farmers increasingly opted for generic alternatives in crop protection products. The fertilizer sector showed weak demand, while the herbicide and pesticide segments experienced reduced activity. The market also faced pressure from adequate supply levels and sluggish consumer behaviour. The shift towards cost-effective solutions in the agricultural sector notably impacted major agrochemical companies, affecting the overall market dynamics.

Analyst Insight

According to Procurement Resource, the Monochloroacetic Acid market is expected to face continued pressure from weak demand in early 2025, particularly in the agricultural and textile sectors. The market trajectory would largely depend on feedstock prices and agricultural sector recovery.

Monochloroacetic Acid Price Trend for the Q3 of 2024

Asia

The monochloroacetic acid market in Asia displayed an upward trajectory during the early phase of Q3’24, influenced by rising feedstock chlorine and acetic acid costs. The market witnessed initial gains as downstream demand showed signs of recovery. However, this upturn was short-lived as market fundamentals stabilized in the latter half of the quarter.

Production rates fluctuated following upstream supply dynamics, particularly in China where both feedstock availability impacted manufacturing sentiment.

Europe

MCAA prices in Europe faced downward pressure despite firm feedstock chlorine prices. The market struggled with poor downstream demand, especially from the PTA and PET sectors. Supply chain disruptions and high energy costs provided some support to prices, but overall market sentiment remained weak amid sluggish buying interest from key end-use industries.

North America

The North American MCAA market demonstrated moderate price gains in Q3 2024. The market found support from rising feedstock costs as both chlorine and acetic acid-maintained firmness. The resumption of normal operations by major manufacturers helped stabilizes supply. However, limited downstream demand kept price gains in check throughout the quarter.

Analyst Insight

According to Procurement Resource, the Monochloroacetic Acid (MCAA) prices are expected to stabilize in the coming months as supply-demand dynamics reach equilibrium.

Monochloroacetic Acid Price Trend for the Q2 of 2024

Asia

In the second quarter of 2024, monochloroacetic acid prices in China experienced overall stability with slight fluctuations. The upstream raw materials, acetic acid, and hydrochloric acid performed steadily, providing a stable cost basis for monochloroacetic acid. The spring plowing season also supported some demand, particularly from pesticide intermediate enterprises fulfilling pre-shipment orders. In April, prices remained relatively unchanged, supported by steady upstream costs and a rebound in downstream glyphosate demand, particularly in the foreign trade market. By mid-May, market conditions showed a slight upward trend, influenced by a temporary reduction in supply due to maintenance at a major production facility.

Despite this, downstream resistance to high acetic acid prices and stabilizing raw material costs tempered further price increases. The market traders predicted that while short-term prices may consolidate weakly due to supply and demand dynamics, the market will be influenced by the balance of upstream raw material availability and downstream replenishment activities. Overall, the monochloroacetic acid market in China is expected to remain stable, with the potential for slight fluctuations based on raw material trends and downstream demand developments.

Europe

The monochloroacetic acid prices in Europe rose due to high upstream costs and low inventory levels during Q2’24. The steady demand from the downstream derivative sector, particularly agrochemicals and surfactants, remained moderate. Prices were bolstered by increased costs of feedstock acetic acid and acetic anhydride, alongside climbing crude oil prices driven by improved demand in the US and China.

The operating rates remained under pressure as raw material availability was low, contributing to the upward price trend. Despite a slight increase in German exports, overall economic conditions, including a decline in industrial output and sluggish end-use industries, did not favor demand recovery.

North America

The monochloroacetic acid in the second quarter of 2024 registered slight fluctuations but an overall stagnant trend, similar to the Asian countries. The stability of the market was particularly driven by the feedstock industries and improving domestic procurement rates.

The short-term gains of the market were also driven by the minute incline in export volumes in the initial stages of the quarter. However, as the quarter proceeded towards its termination, the overseas procurement rates declined amid challenging trade dynamics, escalating prices of transport, and increasing lead times, constricting the export profit margins of the traders and producers, reflected well in the fluctuating pricing dynamics of the commodity.

Analyst Insight

According to Procurement Resource, the price trend of Monochloroacetic Acid is expected to continue rising due to anticipated increases in feedstock costs and tight material availability, although demand from downstream industries is unlikely to improve significantly due to ongoing market sluggishness and production shutdowns among petrochemical giants globally.

MCA (Monochloroacetic Acid) Price Trend for the Q1 of 2024

Asia

The monochloroacetic acid market witnessed a sudden decline towards the termination of the first quarter of 2024 after registering an uptrend due to average consumption in the end-user market and weak downstream purchasing enthusiasm. The prices fell off additionally as even the limited monochloroacetic acid shipments led to increased inventory, prompting continuous lowering of factory quotations to stimulate downstream industries into the market.

Additionally, the upstream methanol market also fluctuated, initially supporting an uptick in the pricing of production but later weakening it due to average procurement by the consumer sector as they focused on essential purchases. Similarly, the downstream market also experienced a decline in prices. Overall, with sufficient market supply, weak downstream demand, and lower prices by manufacturers, the monochloroacetic acid market encountered a slight fall concerning the traders and manufacturers of the market.

Europe

The monochloroacetic acid prices in the European market rebounded in early Q1 of 2024 after a bearish trend in the previous quarters. The upturn was attributed to escalating energy and feedstock prices, compounded by lower operating rates in manufacturing firms. However, downstream demand remained lackluster, keeping market enthusiasm subdued. The further rise in energy and feedstock costs signaled a continuation of the upward price trajectory.

Additionally, crude oil price hikes, prompted by Houthi attacks in the Red Sea disrupting shipping routes, further propelled monochloroacetic acid prices. However, insufficient finished stock availability domestically and sluggish demand from downstream industries has characterized the market dynamics. In addition to this, external factors like decreased exports to both EU and non-EU countries have also influenced prices significantly.

North America

The US monochloroacetic acid prices remained stable due to consistent market dynamics, supported by steady methanol and natural gas prices. Despite the fluctuations in downstream sectors, increasing demand from ethyl acetate and butyl acetate industries supported an uptrend in the pricing of monochloroacetic acid. Also, the challenges proposed by a construction industry labor shortage further posed a problem for the manufacturing units of monochloroacetic acid.

The supply dynamics of the market, however, remained stable in the domestic market. However, the overseas imports of monochloroacetic acid in the region declined due to ongoing challenges from the re-routing of the Red Sea route and the incline in the shipment travel duration.

Analyst Insight

According to Procurement Resource, the price trend of Monochloroacetic Acid is expected to face the consequences of destabilizing downstream markets and oscillating prices of feedstock acetic acid in the next quarters of 2024.

MCA (Monochloroacetic Acid) Price Trend for October - December of 2023

| Product | Category | Region | Price | Time Period |

| Monochloroacetic Acid | Chemicals | USA | 1385 USD/MT | December 2023 |

| Monochloroacetic Acid | Chemicals | Europe | 970 USD/MT | December 2023 |

Stay updated with the latest Monochloroacetic Acid prices, historical data, and tailored regional analysis

Asia

In Asia, particularly China, the monochloroacetic acid (MCA) price trend in Q4 2023 mirrored the volatile trend of its primary feedstock, acetic acid. Starting the quarter with declining prices, the monochloroacetic acid market saw a stabilization phase in November, following the trend in acetic acid prices. However, the surge in acetic acid prices in early December, driven by supply constraints and robust downstream demand, led to a brief spike in MCA prices as well.

This spike was, however, short-lived, as MCA prices corrected downwards towards the end of December, influenced by the adjustments in acetic acid prices and the fluctuating prices of chlorine, the other key feedstock. The overall trend for monochloroacetic acid in Q4 2023 in the Chinese market was characterized by a zigzag pattern, generally trending lower compared to earlier in the year.

Europe

The European monochloroacetic acid market in the fourth quarter of 2023 experienced oscillatory price movements, closely following the trend in the acetic acid market. Supply disruptions and inconsistent demand from downstream industries, which include sectors like agrochemicals and pharmaceuticals, led to significant price fluctuations. The dampened demand for acetic acid in the region, coupled with the variable chlorine prices, contributed to an unstable market environment for MCA. This instability reflected in the fluctuating MCA prices throughout the quarter, ending the year on a somewhat uncertain note.

North America

In North America, the Monochloroacetic acid price trend in Q4 2023 was relatively stable, reflecting the trend in acetic acid prices. Despite some stability in the costs of methanol and natural gas, key components in acetic acid production, the MCA market faced challenges due to a downturn in downstream demand. This was partly attributed to a slowdown in sectors like construction and manufacturing, which impacted the demand for MCA derivatives.

The fluctuating chlorine prices added another layer of complexity to the market dynamics. As a result, the MCA market in the US navigated through a landscape of stable feedstock prices but challenged by reduced demand and fluctuating chlorine costs, leading to a mixed market scenario as the year concluded.

Analyst Insight

According to Procurement Resource, the monochloroacetic acid price trend is expected to stay linear to downward inclined in the beginning months of 2024. The primary reason for the trend is anticipated to be underlying in the slumping price trend for acetic acid and lukewarm chlorine prices.

Monochloroacetic Acid Price Trend for the July - September of 2023

Asia

In the initial phase of the third quarter, the monochloroacetic acid price trend struggled to find the required momentum. This struggle was fueled by the excess influx of the material while the rates of procurement from the end-user industries remained bleak. But in the later months, the sentiments of the monochloroacetic acid market improved at a gradual pace. This trend of the monochloroacetic acid price graph was supported by the increasing cost of feedstock materials and stable demand from the domestic and international industries.

Europe

The third quarter of 2023 experienced a significant decline in the monochloroacetic acid price trend. The interest of consumers was bleak during this phase of the year while the inventories were sufficient. The market also suffered from the economic downturn of the majority of European countries, which was evident in the excess pressure exerted by the rise in inflation and interest rates charged by banks. As a consequence of this, the performance of the downstream industries stumbled throughout the quarter, resulting in a downfall in the monochloroacetic acid prices.

North America

The majority of the third quarter followed a downward trajectory of monochloroacetic acid prices. The market faced this fall as a result of subdued demand and the rising level of inventories. The dip in feedstock prices also supported the decline in the monochloroacetic acid price graph. Further, as seen in the Asia Pacific and European countries, the sentiments of downstream industries were also not in favor of the rise in monochloroacetic acid prices.

Analyst Insight

According to Procurement Resource, the price trend of Monochloroacetic Acid are expected to take a downturn as a consequence of a weak downstream market.

Monochloroacetic Acid Price Trend for the First Half of 2023

Asia

In the Asia-Pacific region, the fall in the price trend of monochloroacetic acid started in the second half of the first quarter. In the first half, the market dynamics were supported by steady demand from the downstream industries and a rise in sales in the agrochemicals and dyes sector. However, soon, the prices of monochloroacetic acid plunged due to a slower recovery of the Asia-Pacific economy and a build-up in inventory levels. In the second quarter, the fall in freight charges and the fall in global demand for monochloroacetic acid led to a downward movement in its price trend.

Europe

The first quarter of 2023 followed a rise in the prices of monochloroacetic acid during the initial months. The momentum of monochloroacetic acid prices was supported by a steady supply of products and a rise in demand from the downstream sector during this phase. However, from the second half, the level of inventories began to rise on account of a hike in production rates while the demand did not change its pace. Further, in the second quarter, the economic conditions and reduction in the purchasing potential of buyers pushed the price trend of monochloroacetic acid towards a negative trajectory.

North America

In North America, the first quarter of 2023 showed oscillations in the prices of monochloroacetic acid. Initially, the surge in market activities of its derivatives supported the growth of monochloroacetic acid prices, and with limited supply, the price trend of monochloroacetic acid surged.

In the second half of this quarter and throughout the second quarter, however, the prices of feedstock materials fell, and along with that, the downstream sector also took a downward toll. The market thus witnessed a huge reduction in the number of new orders, and as a result, the price trend of monochloroacetic acid declined.

Analyst Insight

According to Procurement Resource, the price trend of monochloroacetic acid is expected to decline in the upcoming quarters as the rates of procurement from the downstream industries seem to be struggling amid weak global economic conditions.

Monochloroacetic Acid Price Trend For the Second Quarter of 2022

Asia

The rate of monochloroacetic acid has been declining since the second quarter of 2022. China's market for monochloroacetic acid saw a decline as a result of a plenty of supplies and weak demand. Monochloroacetic Acid prices continued to decline due to low feedstock acetic acid prices. The decline has been linked to a rise in domestic market inventories, which have been supported by higher production and decreased offtakes, followed by a decline in demand from the downstream dyes and agrochemical industries.

But as export demand declined and manufacturers battled supply shortages, growth in China's manufacturing activity slowed in June. The output of monochloroacetic acid and new export orders both decreased, which brought down the price of the substance. Monochloracetic acid prices were approximately USD 955/MT.

North America

Monochloroacetic Acid prices in North America showed favourable market trend in this quarter. The price of the feedstock acetic acid and acetic anhydride were affected by a sharp increase in upstream crude value, which further contributed to the increasing trend in monochloroacetic acid costs. Moreover, from the price charts it is evident that rising demand from the downstream Sodium Mono Chloroacetate and Ethyl Acetate markets drove up regional market prices even higher. In addition, a tight supply, soaring demand, and worries about sky-high inflation drove MCA prices to all-time highs in the USA market.

Accordingly, monochloroacetic acid prices in June were approximately USD 1990/MT. Overall, the factors contributing to the high price of MCA across the region, particularly the demand from the agrochemical industry for insecticides and herbicides, have remained stable.

Europe

A shortage of one of the most important raw materials, acetic acid, was noted in the second quarter of 2022, which was reflected in an increase in monochloroacetic acid prices in Europe. Additionally, as spot prices for MCA rose, regional market trading activities went up. Monochloroacetic Acid prices were around USD 2020/MT during June.

Monochloroacetic Acid Price Trend For the Fourth Quarter of 2021

Asia

Due to decreasing raw material costs, MCA in the APAC region fell in this quarter. For a variety of factors, upstream acetic acid was found to be growing in October, placing pressure on downstream products to display buoyancy. However, during the quarter, the price of acetic acid plummeted by more than 10%, creating a major reduction in the price of different downstream derivatives in November.

In December, MCA prices were around 95,000 INR/MT ex-depot Mumbai. Due to increased demand for the usage of MCA for celluloses, agrochemicals, high-foaming surfactants, and personal care items, Asia Pacific is predicted to rise at a much faster rate than the rest of the world by 2022. Furthermore, the region's market has grown significantly due to rapid expansion in the chemical and materials sectors, as well as increased demand for choloracetic acid from other industries.

Increasing advancements and improvements in the textile sector in Asia Pacific countries such as Indonesia, India, and China, among others, are likely to raise demand for MCA and drive revenue growth in the area.

Methanol, acetic acid, and heavy feed inventories for petroleum refinery would see tariff reductions in India starting in February 2022. Companies that use chemicals as raw resources are positioned to gain from the duty reduction, while chemical producers are likely to suffer. This decrease in feedstock acetic acid can cause a downward trend in the price of MCA.

Europe

In the fourth quarter of 2021, there was a scarcity of crucial raw materials across Europe, leading to higher MCA prices on the local market. As resources became increasingly scarce, manufacturers sought things from a multitude of different sources. The availability of MCA on the market increased as the quarter progressed. The pharma and adhesives sector's offtakes stayed high in Q4 in terms of demand. In October, FOB Hamburg MCA prices were1785 USD/MT, but by December, they had dropped to 1630 USD/MT.

North America

North America is expected to account for a disproportionately large share of revenue during the forecast period, owing to growing demand for monochloroacetic acid from a variety of end-use industries, including agriculture, medical and pharmaceuticals, and chemical, for the manufacture of agrochemicals, ibuprofen, and vitamins. Additionally, the presence of major manufacturers in the region is a significant factor driving the market's revenue growth.

Monochloroacetic Acid Price Trend For First, Second and Third Quarters of 2021

Asia

Nouryon (Amsterdam, Netherlands) and Atul successfully began manufacturing at Anaven in April 2021. Anaven is India's largest MCA production complex, with a current capacity of 32,000 MTPA and the potential to expand to 60,000 MTPA quickly. In December 2021, the plant was significantly extended.

MCA supply in China remained constrained in the first quarter of 2021 due to plant turnarounds over the Chinese Lunar New Year holidays in February. The downstream manufacturing plants' margins were lowered due to a lack of supply of the feedstock acetic acid and liquid chlorine.

Demand from the downstream segment increased as offtakes from the personal care, food, and pharma sectors remained stable. Increased pricing of essential feedstocks produced a multifold increase in MCA prices, which settled at 1250 USD/MT FOB Shanghai in March.

As a result of the abrupt reversal of several large upstream production facilities in the second quarter of 2021, the MCA market experienced a demand-supply imbalance. In China, however, a sharp increase in the price of the raw ingredient acetic acid aided the pricing trend in the local market. As commercial and industrial operations improved in the Northeast Asian region, demand from downstream industries remained strong.

In India, however, due to the impact of the second COVID wave, raw material prices fell due to less industrial activity and lower demand from the downstream market. As a result, producers reduced their offerings by specific margins, with Ex-Works Mumbai MCA prices estimated at 1073 USD/MT in Q2 2021.

During Q3, the general market prognosis for MCA in the Asia Pacific region showed an upward tendency. Back-to-back positive revisions in upstream acetic acid prices in India contributed to a new rising trend in MCA pricing in the domestic market. Following the upward trend, Ex-Works MCA prices in western India increased from 1106 USD/MT to 1201 USD/MT in the third quarter.

Because the product is primarily imported from China, a slew of problems loomed over the supply chain this quarter, causing Chinese origin cargo deliveries to be delayed. Anaven, which has a stranglehold on the MCA market in India, was heard positively modifying its rates to protect its margins from the steady rise in acetic acid prices.

Europe

Due to low stockpiles and continuous offtakes from the downstream market, European MCA supply remained limited during the first quarter of 2021. Due to a shortage of raw materials and a transportation lag from the western region due to serious freeze weather, the Northwest regional facilities functioned at a slow pace. As the downstream food and pharma markets improved, demand skyrocketed.

As different US plants resumed production following the winter storm, access to feedstock chemical increased slightly, resulting in a reduction in MCA supply limitations in the second quarter of 2021.

A shortage of critical raw materials was noted across the European region in the third quarter of 2021, resulting in higher MCA costs on the local market. Manufacturers sought items from a variety of sources as materials grew increasingly difficult to come by. As the quarter came to a close, the provision of MCA on the market improved. In terms of demand, the construction sector's offtakes remained high in Q3.

North America

During the first quarter of 2021, regional MCA supplies were limited due to limited availability of acetic acid due to disruptions in production at numerous regional plants. The stoppage of Formosa Plastics' 910,000 MT per year feedstock chlorine factory in the first half of Q1 added to the crisis. Due to lower pricing than the domestic market, spot buyers in the region grew more inclined to the Asian market. Despite a regional shortage that prompted a multifold increase in MCA prices in the timeframe, demand remained buoyant due to improved intake from the downstream pharmaceutical and food sectors.

After seeing a substantial increase in pricing throughout the second quarter, market sentiment for MCA in the North American region stabilised in the second quarter. Supplies improved in the United States when production in the Gulf region revived, owing to higher upstream acetic acid output. With the resumption of industrial activities, demand from the downstream surfactant, textile, and coating sectors grew.

Spot MCA prices in the North American region rose throughout the most of the third quarter, owing to high demand from the agrochemical, pharma, and surfactant industries. The spike in pricing was fueled in part by rising acetic acid costs from mid-July to the last week of September.

During the hurricane season, numerous chlor-alkali production operations on the US Gulf coast shut down, causing supply disruptions throughout the region. However, production slowed at the end of Q3, and MCA prices fell in early Q4 as the feedstock's rising trend slowed.

Monochloroacetic Acid Price Trend For the Year 2020

Asia

The chloroacetic acid market in China climbed and then declined in July, with the overall climate becoming more sluggish. The downstream demand improved since the beginning of the month, raw material costs continued to rise, the expense of chloroacetic acid support rose and manufacturers offered lower MCA prices. Even though the price of liquid chlorine remained high since the middle of the month, the acetic acid market had been loose, causing the price of chloroacetic acid to fall.

Due to lower demand for downstream pesticides, pharmaceutical intermediates, and other industries in the second half of the month, China's demand for chloroacetic acid declined, and prices continued to fall. In August, China's investor sentiment remained negative, with a general lack of transaction activity. Chloroacetic acid producers had a high operating load, with low downstream demand, resulting in a growth in inventory, shipping pressure, and a limited range of lower prices.

Due to restrictions on international shipments across multiple trade channels along Southeast Asia, India's monochloroacetic acid (MCA) supply remained limited, despite worries of a new coronavirus outbreak in Europe. Consistently growing acetic acid feedstock prices also played a significant effect in constraining supplies.

Rising agrochemical demand in APAC as a result of agricultural expansion prompted the Indian government to implement programmes such as the PLI plan to boost local pesticide manufacturing. This was expected to relieve supply pressure in India, resulting in future price stability for MCA, which is used in a variety of herbicides.

Europe

Domestic demand slowed as a result of the pandemic, causing trade networks to the APAC area to become congested. With the installation of new plants from PCC in Poland and Neuryon in the Netherlands, monochloroacetic acid availability in the region improved significantly. This intended to improve domestic supply, allowing for long-term price stabilisation. Due to increased demand for agrochemicals in North America and the Asia-Pacific region, exports increased towards the end of the year.

North America

High agricultural investment in the United States, Canada, and Mexico shaped the local market demand that rebounded after the COVID impact. Due to the coronavirus epidemic, which delayed market activity in the western hemisphere in Q4, access of feedstock acetic acid in the US remained constrained. As a result, its price increased, resulting in higher production costs for the derivative monochloroacetic acid.

Procurement Resource provides latest prices of MCA or Monochloroacetic Acid. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Monochloroacetic Acid

MCA is a chlorocarboxylic acid and a haloacetic acid. It is extracted from acetic acid. It is a conjugate acid of a chloroacetate. In appearance, it a colourless to light-brown crystalline material. It is miscible in water and sinks in it. It is combustible in nature. It is one of the most important halogenated derivatives of acetic acid.

Monochloroacetic Acid Product Details

| Report Features | Details |

| Product Name | MCA (Monochloroacetic Acid) |

| Industrial Uses | Carboxymethyl Cellulose Or CMC, Pharmaceuticals, Agrochemicals, Dyes, Cosmetics |

| Chemical Formula | C2H3ClO2 |

| Synonyms | Chloroacetic Acid, 79-11-8, 2-Chloroacetic Acid |

| Molecular Weight | 94.5 g/mol |

| Supplier Database | Acros Organics, Nouryon, CABB Group GmbH |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Monochloroacetic Acid Production Processes

- Production of MCA via Chlorination; and via Hydrolysis

In this process, acetic acid is chlorinated with acetic anhydride as a catalyst, which results in the formation of Monochloroacetic Acid with dichloroacetic acid and trichloroacetic acid as impurities. This product is further separated and refined to obtain the desired product.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com