Product

Steel Price Trend and Forecast

Steel Price Trend and Forecast

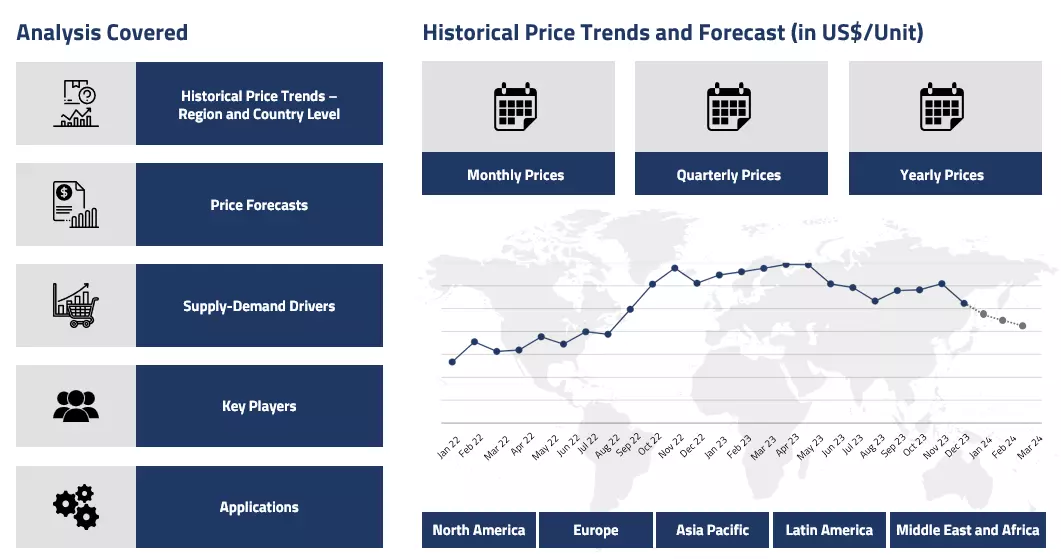

Steel Regional Price Overview

Get the latest insights on price movement and trend analysis of Steel in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Steel Price Trend for Q1 of 2025

Asia

Asian steel markets showed mixed performance in the first quarter of 2025. China's economic stimulus measures announced in late 2024 initially created positive momentum, with steel prices rebounding from three-year lows. However, this optimism faded as demand remained sluggish, particularly in the construction sector, which continued to face challenges from the property market downturn.

Steel Price Chart

Please Login or Subscribe to Access the Steel Price Chart Data

Indian steel producers struggled with persistent pressure from imports, which remained elevated despite government concerns. Raw material costs fluctuated throughout the quarter, with iron ore and coking coal showing volatility that complicated pricing strategies for mills. Several Asian producers announced production cuts to address the oversupply situation, though these had limited impact on market prices as Chinese exports continued to flow into regional markets at competitive rates.

Europe

European steel markets experienced a marked turnaround in Q1’25. After hitting multi-year lows in late 2024, prices steadily climbed throughout the quarter, led by major producers like ArcelorMittal who successfully implemented multiple rounds of price increases. The automotive sector, while still below pre-pandemic production levels, showed signs of technical recovery, providing support for flat steel products.

Supply constraints emerged as some mills maintained reduced production schedules from winter, creating tighter availability particularly for specialized grades. The implementation of new carbon border adjustment mechanisms added complexity to import strategies, effectively raising costs for non-EU steel entering the market. Service centres actively rebuilt inventories during the quarter in anticipation of further price increases, creating additional momentum in the market.

North America

North American steel markets experienced dramatic volatility in Q1’25, dominated by the implementation of Trump's blanket 25% tariffs on steel and aluminium imports in March. This policy shift triggered immediate price surges across all steel products as buyers scrambled to secure material ahead of the tariffs. Mills quickly capitalized on the opportunity, withdrawing previous offers and reissuing them at substantially higher levels.

The abrupt elimination of exemptions for Canadian and Mexican steel created significant supply chain disruptions, especially for manufacturers with integrated cross-border operations. Distributors reported extended lead times and allocation scenarios reminiscent of the pandemic period. Smaller manufacturers voiced concerns about absorbing these sudden cost increases, while construction projects faced budget pressures from escalating material costs.

Analyst Insight

According to Procurement Resource, the Steel market entered 2025 with significant regional divergence and heightened uncertainty. Trade tensions and retaliatory measures threatens to further fragment global markets, while structural overcapacity issues remained unresolved.

Steel Price Trend for the Second Half of 2024

Asia

Steel prices in Asia faced significant downward pressure during the second half of 2024. The region's largest producer, China, struggled with weak domestic demand particularly in construction and manufacturing sectors. This surplus production capacity forced Chinese mills to increase exports at competitive rates. In India, domestic steel prices dropped to three-year lows, with hot-rolled coils (HRC) trading substantially below their 2022 peak levels.

The influx of cheaper imports, which surged by 68% in the April-June quarter compared to the previous year, further depressed local pricing. Raw material cost declines, including iron ore and coking coal, allowed producers to maintain margins despite lower selling prices. Some optimism emerged in late September when China announced economic stimulus measures, temporarily boosting market sentiment.

Europe

European steel markets experienced volatility throughout the latter half of 2024. After prices bottomed out in August-September, reaching their lowest levels since 2020, major producers including ArcelorMittal implemented significant price increases for hot-rolled coils in October. Other manufacturers like NLMK La Louviere followed with their own increases. This upward correction was driven by rising raw material costs and the ripple effects from China's economic stimulus announcement. Service centres responded by raising their offers for smaller tonnages. The automotive sector, a key steel consumer in Europe, continued to underperform, though market participants anticipated a technical recovery in early 2025. The ongoing trade tensions with the US created additional uncertainty for European producers.

North America

North American steel markets showed early signs of recovery in the second half of 2024 after prices had nearly halved since the beginning of the year. The market stabilized faster than other regions, potentially indicating it had reached its bottom. However, the announcement of potential new tariffs by President-elect Trump created significant market uncertainty.

His plan to impose 25% tariffs on all Mexican and Canadian imports, along with additional 10% tariffs on Chinese goods starting January 20, 2025, dominated industry discussions. While some domestic producers welcomed these protective measures, others expressed concerns about potential retaliatory actions and increased costs for American consumers. The tariff announcements created a wait-and-see attitude among market participants, temporarily slowing trade activity.

Analyst Insight

According to Procurement Resource, the Steel industry will likely enter 2025 with cautious optimism as rising raw material prices, Chinese stimulus measures, and potential trade barriers pointed toward price stabilization.

Steel Price Trend for the First Half of 2024

Asia

During the first half of 2024, the steel market exhibited noticeable fluctuations. Following some initial momentum, the balance between supply and demand in India largely kept the market steady throughout the period. The country's long general election process also contributed to the steel market's overall stability.

While the market remained anchored due to steady upstream and downstream factors, weak global demand exerted pressure on domestic prices as export opportunities were limited. China continued to dominate as the leading producer and supplier in the global steel market. Overall, sentiments remained mixed across the first half of the year.

Europe

European steel markets faced persistent challenges due to ongoing logistical and freight disruptions. Delivery times for steel shipments saw significant delays, primarily driven by increasing security threats in the Red Sea. The Suez Canal, a critical link between Asia and Europe, experienced a sharp drop in vessel traffic, compounding the situation. Additionally, rising nickel and iron ore costs from key export countries further intensified pricing pressures. Increased imports from Asia led to concerns among domestic producers as competition in the European market grew fiercer.

North America

The North American steel market showed a positive trend throughout the first half of 2024. Prices climbed steadily, bolstered by the expansion of the automotive and construction sectors. Despite cautious market sentiment caused by the US Federal Reserve's decision to delay interest rate cuts, the trade dynamics remained stable. Further support came from a growing industrial sector during the summer, which led to increased imports from Asia.

Analyst Insight

According to Procurement Resource, the Steel market is expected to show improvements in the post-monsoon season. In India, large public sector construction and infrastructure investments will positively drive the steel market.

Steel Price Trend for the Second Half of 2023

| Product | Category | Region | Price | Time Period |

| Steel | Energy, Metals and Minerals | India | 4175 USD/MT | July 2023 |

| Steel | Energy, Metals and Minerals | India | 3780 USD/MT | December 2023 |

Stay updated with the latest Steel prices, historical data, and tailored regional analysis

Asia

The steel market experienced notable fluctuations in the last two quarters of 2023. Early in the third quarter, a rise in iron ore prices, driven by a resurgence in the Chinese real estate sector, led to a 7% increase in steel prices across the region. However, as inventories grew and domestic consumption in India declined, prices started to waver. The monthly average prices in the Indian market dropped from around 4175 USD/MT in July '23 to about 3780 USD/MT in December '23, marking an overall decline of approximately 9% over six months. This period ultimately saw a mixed market performance.

Europe

In Europe, the steel market experienced a consistent downward trend in the latter half of 2023. The ongoing economic instability since the onset of the Russian conflict led to reduced spending in construction and related sectors. This diminished demand from end users resulted in struggling steel prices, with a generally slumping trend throughout the period.

North America

The steel market in North America saw fluctuating prices during the mentioned timeframe. Prices remained low throughout the third quarter but began to recover at the start of the fourth quarter. However, shipping disruptions in the Red Sea, which significantly reduced the number of vessels passing through the Suez Canal, led to a decline in demand. Additionally, the New Year holidays contributed to this downward trend.

Analyst Insight

According to Procurement Resource, the price trend of Steel is estimated to showcase a bearish trend in the coming months, given the trading challenges and declining global construction activities.

Steel Price Trend for the First Half of 2023

Asia

Asian steel market experienced fluctuating price trend throughout the said period of the first half of the year 2023, majorly tilted towards the lower side of the price curve. Owing to the restricted industrial and construction activities because of the global COVID-19 pandemic, steel usage has been limited.

This led to a surplus stockpile and overfilled inventories amidst a relaxed inflow of raw materials. Consequently, the prices were low in order to push the supply movement and vacate the inventories. Some reverse fluctuations were observed at the quarter shift, but the general market sentiment remained low.

Europe

The European steel market witnessed a mixed price trend in the first two quarters of 2023. After battling immensely high energy and power bills and economic inflation in the wake of the Russia and Ukraine conflict, industrial activities started picking some pace this year. With warming downstream demands, the prices inclined in the first quarter. However, the second quarter started dipping down again, driven by the lowered feedstock costs. Overall, oscillating market sentiments were observed.

North America

The North American steel market almost replicated the European steel market trend. The prices first lifted in the first quarter and declined in the second. Downstream demands drove the market sentiments. The regular industrial activity kept a positive outlook in the first three months; however, the rising interest rates and inflation started taking a toll after that, and the demands dipped, resulting in backtracking of the steel price trend.

Analyst Insight

According to Procurement Resource, not much improvement is anticipated in the steel markets going forward. The global economy is having a tough time, which suggests a lack of support for the industrial sectors.

Steel Price Trend for Second Half of 2022

Asia

Steel prices oscillated in the global market in the third and fourth quarters of 2022. It was expected that with the ease of the covid restrictions in the Chinese region, the prices and demand for steel will bloom. However, the stagnant steel market depressed the price trend for steel. The weak domestic demand, high exports, declining prices of coking coal, and increasing pressure from the banking crises in the Asia-Pacific region aided the downward trajectory of steel prices.

In the last quarter, the Indian government ease the export duties on steel. This decision was mainly influenced by two factors- the domestic prices of steel were no longer responsible for inflation as they were sufficiently available in the domestic market and the export curb led to contraction of exports. This decision is expected to increase exports in the international market and will improve the overall market dynamics of steel.

Europe

In the European region also, the steel prices failed to gain the required momentum as significant steel destocking was observed. The weak demand, stockpiling, and rising inflation, all caused the prices of steel to remain on the negative side.

North America

The North American market remained favourable for the prices of steel and its related products. The market saw high demand from the end-sector industries, mainly automotive, thus the prices of the commodity inclined in the region. However, this incline was short-lived and soon the prices started falling. The hiked interest rates, rising inflation, and contracting of the construction sector caused the baulking of consumers. Hence, the price trend for steel kept towards the lower end of the scale.

Analyst Insight

According to Procurement Resource, steel prices are likely to oscillate in the global market. The weak demand, rising inflation, and inclining input costs are likely to affect the steel market adversely in the coming months.

Steel Price Trend For the Second Quarter of 2022

Asia

In the Asian market, there were concerns about the supply in Q2 of 2022, plus the production costs due to the energy prices continued to affect the price in Q2/2022. Steel prices in Tangshan City increased by 13% from the beginning of Q1 to almost the end of the quarter, while the price of CFR steel in Southeast Asia increased by 33% over the same period.

The crisis between Russia and Ukraine has caused suppliers in India, Japan, and South Korea to concentrate more on the European steel markets, which has given developing Chinese companies the chance to establish themselves as "dominant" suppliers in the Asian market. This trend continued in Q2 of 2022 after the EU boosted its HRC import quota from South Korea to 27% and from India to 62% as of 1 April.

North America

For most of 2022, US steel prices were significantly impacted by weak downstream demand, conservative service centre purchasing, and a continually large supply. Prices have decreased by 48 percent since the start of 2022 as a result of a market glut that has persisted since steelmakers overshot demand in the fourth quarter of 2021.

US Hot-Rolled Coil Index started the second quarter at 1,500 USD/st, matching the year-to-date high set in early April on an ex-works Indiana basis.

Europe

In Q2 2022, European steel prices fell as a result of declining manufacturing demand and restocked inventories as a result of Russia's invasion of Ukraine. Since reaching a record in March, hot-rolled coil, the standard flat steel product, has decreased by about a third. For the first time since February, prices were below 1,000 EUR/MT (1,042 USD).

Steel Price Trend For the First Quarter of 2022

Asia

In the third week of February 2022, China’s largest steelmaker, China Steel Corp, announced to increase prices by 2.44% as local demand improved, accelerating the inventory build-up. Angang Steel Co and Baowu Steel Group Ltd. also raised domestic steel prices in the range of 31.55 USD/MT to 63.11 USD/MT. As demand for steel improved globally, the market prices went up in the region amid limited supply from Japan and South Korea.

Europe

In March, the steel prices went up in Europe, increasing by almost 10% within the first two days of the month. The price rise resulted from the Ukraine-Russia war, which increased metal prices globally as input costs like energy and raw material and input shortages shot up. In March, the benchmark steel prices in Europe increased to 1160 EUR/MT as exports from Ukraine were disrupted by the war while Russia reduced its steel supplies to Europe, which tightened the market.

North America

Prices in the US were in a downtrend in the beginning of 2022 after witnessing record highs in the previous year. As supply improved, the prices went into a downward spiral which only seemed to recover during the Ukraine-Russia war situation, which caused disruptions in the global supply chains. As pig iron supplies in the US plummeted, the raw material prices went up, causing manufacturers to hike the steel prices.

Latin America

In March, the Brazilian steelmakers announced price hikes for the next quarter to recover weak margins due to the Ukraine-Russia war, which increased raw material and input costs. On March 11, steel slab FOB prices in Brazilian ports were recorded at 1100 USD/MT, increasing by 250 USD/MT within a week.

Steel Price Trend For the Fourth Quarter of 2021

Asia

In FY22, India's crude steel production is expected to expand by 18 % to 120 MT, owing to rising consumer demand. The Indian steel sector's expansion has been fueled by local accessibility of raw materials like iron ore and affordable labor. As a result, the sector's contribution increased significantly to India's manufacturing output.

China's crude steel production will likely be regulated in 2022 and beyond, limiting yearly output to levels comparable to those in 2021. This measure was intended to provide the steel sector greater flexibility in transitioning to a low-carbon economy, as well as to calm market speculation about steel output cuts, which have generated price volatility.

Europe

The current prices stand at an average 922.7 EUR/MT. The prices, as measured by different industry indices, reached record highs and show no signs of abating in 2021. Plate prices, on the other hand, increased at a slower rate in Q4 2021, and analysts anticipate that prices will settle in early 2022.

Additionally, the European government is seeking to implement a carbon border adjustment tax. This suggests that European legislation is becoming much stricter in order to contain the steel industry's carbon emissions. The measure could create difficulties for steel producers in EU member states.

North America

Imports of certain steel goods, including as hot-rolled coil, grew in the latter months of 2021, as rising US prices made lower-cost imports more appealing despite taxes. Imports will continue to play a big role in the US market as long as regional costs stay significantly higher than global prices. Although imports to the United States are likely to increase sufficiently in 2022 to maintain pressure on local prices, which reached record highs in 2021, these deliveries will not necessarily reflect an import spike.

Latin America

After a year of strong domestic demand for the alloy in 2021, which drove prices to an all-time highs, the Brazilian sector is likely to face downward pressures in 2022 due to economic recession, full inventories, and declining end-user demand.

Steel Price Trend For First, Second and Third Quarters of 2021

Asia

Prices continued to rise, reaching an all-time high of 58,000 INR/MT (ex-Mumbai) for benchmark hot-rolled coil (HRC) goods. This was due to the supply constraints and an increase in demand from the construction, automotive, and white goods sectors. In January 2020, the same grade of HRC was selling for 37,500 INR/MT in the Mumbai commodities market.

Domestic flat HRC prices had risen by 40% since April 2020 at the conclusion of the fiscal year ending March. Prices for long steel, or TMT, were approximately 30% higher within this one-year timeframe. In April 2021, Indian producers announced additional price increases in HRC of up to 1,000-2,000 INR/MT.

HRC was being provided in April 2021 at a price range of 59,700-60,000 INR/MT, up from 36,950 INR/MT in April 2020. This was the highest since 2008, according to the U.S. Census Bureau. India's exports increased by 121.6 % year on year in April 2021, compared to 2020. The government prolonged anti-dumping duties on a certain variety of steel products until December 15, 2021, in order to protect domestic manufacturers from low-cost imports from nations such as China, Japan, and Korea.

India was the world's second-largest manufacturer of crude steel in October 2021, with a 9.8 MT output. Despite being affected for a year by a lack of construction activity caused by covid-19, the steel sector recovered and reported a 25.6 % increase in crude steel output from January to August 2021.

Both crude steel and pig iron output in China declined year on year in December, with the former’s output falling by 6.8%, to 86.19 million mt, but rebounding significantly from November, climbing 20.3 % and 13%, respectively, month on month. According to industry sources, the month-on-month increase in crude steel output was consistent with market forecasts, as Chinese mills began ramping up production following the completion of output reduction requirements for 2021 in late November.

Bulk commodity prices increased in the first five months of the year, owing to a resurgence in global demand and government stimulus. However, Chinese mills were instructed to reduce production. These factors contributed to a 42% increase in China's prices since the start of the year. In FY'21, the median price of the eight primary steel products climbed dramatically over the previous year, with the biggest increase of 39.4 % for hot-rolled coils. The smallest rise, 33.6 %, was in grade-3 rebar. Other goods prices increased between 34% and 39% year on year.

Europe

In May 2021, a demand recovery fueled by government fiscal stimulus exceeded a modest gain in steel production in H1 2021. Since November 2020, European prices climbed by 81%, while steelmakers' margins increased by 300%, despite enormous rises in raw material costs. Additionally, EU steelmakers ceased giving spot market rates near 1050 EUR/MT (1247 USD). As the economy recovered and manufacturing demand increased, demand exceeded supply, driving the prices skyward due to supply chain limitations and material shortages.

North America

Prices remained elevated as a result of the enormous gap between demand and supply, as well as the time required for supply to keep pace and refill depleted inventories. Numerous plants in the United States suspended output during the opening months of the COVID-19 epidemic shutdowns, assuming the world was heading for a deep recession. The drop in demand for iron ore and steel, on the other hand, was brief. The pandemic's effect on consumer spending habits and consumption patterns resulted in significantly larger demand than anticipated in the industry.

This, along with a very restricted supply due to the closure of numerous mills, resulted in a sharp increase in the price of the alloy, with the price of hot-rolled coil rising more than 200 % to 1,800 USD/T (short tonne) in July 2021. Global supply chains also contributed to price instability for US steel; for example, the semiconductor chip shortfall slowed automotive production, cutting the demand for the alloy while the shortage lasted. At the end of 2021, the hot-rolled coil index was estimated to be 1,500 USD/S EXW Indiana, up from 1,009 USD/T at the start of the year and then down from a record 1,960.25 USD/T in September.

However, as the issue was remedied, demand for the alloy within that industry grew again, exerting additional downward pressure on its prices.

Latin America

Plants in Brazil profited from a distribution side restocking drive. Crude steel production grew 14.7% year on year to 36.03 MT in 2021, with the industry working at 73% of generation capacity. In 2021, imports accounted for the majority of market replenishment, at 4.97 MT a 144.1 % increase over 2020.

Steel Price Trend For the Year 2020

Asia

China remained the world's top steel producer in 2020, producing 1064.8 MT of it, or over 57% of all steel produced globally. Despite the growth in China's industrial production of the alloy, the country's imports climbed by 150% in the same year to 38.56 MT. Imports increased as companies battled to meet soaring demand sparked by government efforts to bring the economy out of a coronavirus-induced recession. Prices recovered out of a deep hole in April 2020 and remained on an upward trend for the remainder of the year as economic and industrial activity resumed.

The alloy performed better than projected, with prices climbing for most of the year. On 21 December 2020, hot-rolled coil (HRC) prices in Shanghai jumped to 4,970 RMB/MT, the highest level since the pricing series began in February 2016. China was followed by India, which produced 100.3 MT of steel in FY20.

Prices in Chennai reached 66.47 INR/kg in the fourth quarter of 2020. China's increasing demand for Indian iron ore claimed to have dramatically improved the steel price in India at the end of 2020. Iron ore prices began climbing in August'20 and peaked in May-June'21, owing mostly to the demand-supply imbalance.

Europe

The COVID-19 pandemic continued to run across Europe, affecting all sectors that rely on steel. In the second quarter of 2020, its consumption in the EU declined by 25% year on year, following a decline of 12% in the first quarter. This was the steepest decline in its usage the EU ever recorded. Imports declined further in 2020, continuing the trend established in 2019, but this time mostly as a result of the pandemic's impact on domestic demand.

As generally anticipated, the extraordinarily low trend in the demand in the second quarter of 2020 was a result of the economic and industrial lockdown imposed in reaction to the Covid-19 pandemic. Industrial activity resumed in the third quarter, following the government's COVID measures being lifted in significant part, decreasing the prices. In the upstream market, the average weekly price assessment for domestically delivered steel reinforcing bar (rebar) in Northern Europe was 573 EUR in December 2020.

North America

The price of the alloy per metric tonne ranged between 500 USD and 800 USD in March 2020, prior to the COVID-19 epidemic. The demand initially decreased during the coronavirus pandemic, but quickly increased. At one point, prices were more than 300% more than they were before the epidemic, at more than 1,900 USD/MT.

Latin America

The demand in the LATAM region fell by 10.1% in 2020 as a result of the LATAM countries' blanket shutdown of industry. Additionally, the epidemic extended the demand-supply imbalance, resulting in a consistent price range in Brazil throughout the year. Domestic prices in Brazil, particularly coil and rebar, remained relatively stable as companies refrained from raising prices in response to the Covid-19 crisis. In April 2020, the price of hot-rolled coil remained stable at a mean of 2,636-2,655 BRL/MT($516-519).

Procurement Resource provides latest prices of Steel. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Steel

Steel is an alloy of iron and carbon and chromium. It is used as a significant component in buildings, infrastructure, tools, ships, trains, automobiles, machines, appliances, and weapons because of its high tensile strength and low cost. Iron is known as the base metal for Steel.

Steel Product Details

| Report Features | Details |

| Product Name | Steel |

| Industrial Uses | Construction, Infrastructure, Structural Engineering Applications, Automobiles, General Industrial Applications |

| Supplier Database | ArcelorMittal S.A, Hindustan Steel Corporation (LTD.), Tata Steel Limited, Nippon Steel Corporation |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Steel Production Process

- Production of Steel via Iron Ores.

Steel can be produced in both blast furnaces as well as by electric furnaces via iron ores. While in the blast furnace steel is produced by converting liquid iron and steel scrap into steel. Electric furnaces uitlises melting scrap steel or direct reduced iron to produce steel.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Related News

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com