Product

Cement Price Trend and Forecast

Cement Price Trend and Forecast

Cement Regional Price Overview

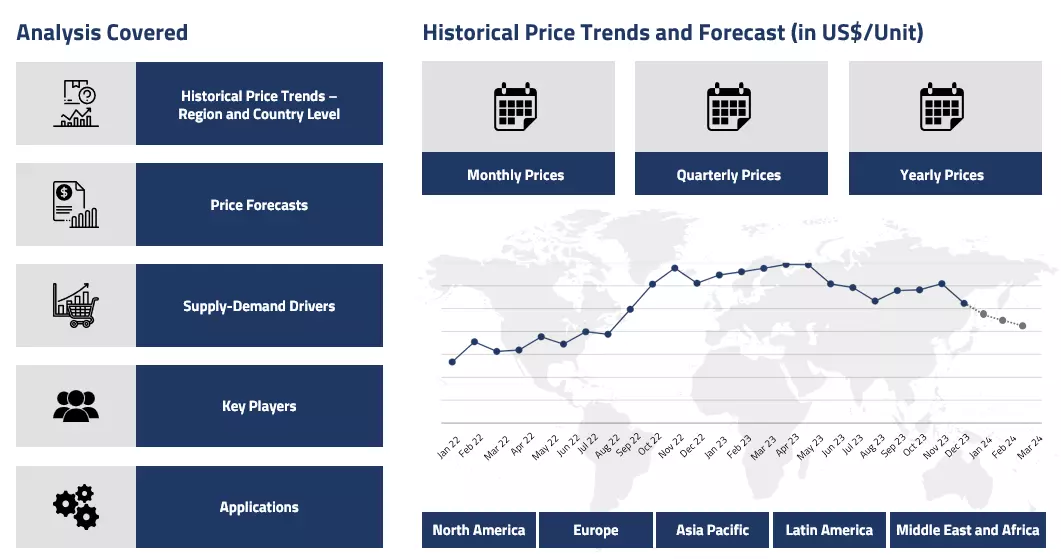

Get the latest insights on price movement and trend analysis of Cement in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Cement Price Trend for Q1 of 2025

| Product | Category | Region | Price | Time Period |

| Cement | Energy, Metals and Minerals | China | 47 USD/MT | January 2025 |

Stay updated with the latest Cement prices, historical data, and tailored regional analysis

Asia

Throughout Q1 2025, Asia's cement markets were characterized by weak demand and downward pressures in China and India. Prices moved steadily down throughout the quarter in China, an indication of weak construction activity and seasonal weakness that normally keeps demand in check. There were no wild swings, indicating a subdued price environment more influenced by cautious market fundamentals than cost volatility. The prices were about 47 USD/MT (Spot FD) during January in the Chinese markets.

Cement Price Chart

Please Login or Subscribe to Access the Cement Price Chart Data

Domestic Indian manufacturers first tried to raise prices but soon rolled back as demand proved slower than anticipated. Increasing fuel prices particularly for petcoke and lower utilization rates also negatively affected margins. Cement producers that were dependent on imported petcoke were affected more because logistics costs were higher, whereas domestic coal availability helped those with access to it partly cushion the impact. Regionally, the southern part of India witnessed significant weakness in particular, whereas the east was relatively stable; nevertheless, overall pricing direction was still underwhelming.

Europe

The cement industry in Europe witnessed a comparatively more stable pricing scenario, but in the context of more general macroeconomic uncertainty. Building activity continued to be weak in early 2025, particularly in the residential sector, due to continuously elevated interest rates and poor private investment. Yet, some areas profited from stepped-up public infrastructure expenditure and initial indications of stabilization in the macroeconomies. Germany, for instance, reflected wary optimism as deployments of infrastructure funds started to manifest themselves. These funds benefited construction demand, but only to a limited extent.

Other areas like the Netherlands, Spain, and some parts of Scandinavia saw similar patterns of marginal recovery. Even as underlying issues like shortages of labor and higher input prices continued, cement prices in most European markets remained stable or saw small upticks. The relative stability implies the worst of the contraction may be behind it, with hopes of sustained support from government-sponsored construction and renovation programs.

North America

The North American cement market also reflected the ambiguity of other regional cement markets. The tariff uncertainties on cement and other building material supplies disrupted market sentiment and brought about large-scale procurement uncertainty. Both the United States and Canada, being reliant on bilateral building material trade, stood at risk of cost inflation and project delay.

Such regulatory overhang in addition to already increasing raw material costs resulted in weakening demand from contractors and developers. Consequently, most construction works were either delayed or rescheduled, especially in the infrastructure sector. There was moderate price volatility, but generally, sentiment was bearish, based on risk-averse contracting methods, tighter budgets, and caution in material procurement.

Analyst Insight

According to Procurement Resource, cement price curve is likely to experience modest recovery, supported by stabilizing feedstocks costs and gradual demand led by infrastructure development projects. Nevertheless, weak residential activity and competitive markets will likely curtail substantial price appreciation in the near term.

Cement Price Trend for the Year 2024

Asia

Cement prices saw a notable rise, primarily due to strong demand from both residential and infrastructure sectors. In countries like India and Pakistan, the construction boom was fuelled by post-pandemic recovery and a surge in government-funded projects. With labour shortages easing and more materials becoming available, demand from the real estate sector pushed prices higher.

Southeast Asia, particularly Vietnam and Thailand, experienced moderate price increases due to stable demand for cement, spurred by ongoing urban development and infrastructure work. Despite challenges like inflationary pressures, cement producers in China managed to maintain relatively stable prices, thanks to a large-scale production capacity and state-controlled pricing mechanisms.

Europe

Cement prices rose steadily throughout the year, driven by increasing production costs, energy price hikes, and a demand surge for residential and infrastructure projects. Western European countries such as Germany, France, and the UK saw significant price hikes due to challenges in raw material sourcing and labour shortages, as well as heightened energy costs linked to the Ukraine crisis. This led to higher overall production costs, which were passed on to consumers. In Central and Eastern Europe, however, price hikes were more moderate but still noticeable, as countries like Poland and Romania benefited from strong EU-driven infrastructure initiatives. These projects kept cement demand steady, leading to moderate price increases in these regions.

North America

Cement prices also followed an upward trajectory, particularly in the U.S. and Canada. Strong demand from the housing sector and major infrastructure projects, boosted by government spending, played a significant role in driving prices up. The U.S. saw substantial price increases in the South and West due to high construction activity and a growing demand for residential and commercial buildings. Raw material costs and energy expenses also pushed prices higher. In Canada, although the price increase was not as sharp as in the U.S., the cement market still saw gradual rises due to a continued need for housing and infrastructure development.

Analyst Insight

According to Procurement Resource, the Cement industry’s outlook for 2025 appears to be shaped by ongoing construction activity, government-backed projects, and raw material cost pressures. While demand is expected to remain strong, especially in infrastructure, the sustainability of price increases will depend on global supply chain conditions and regional economic factors.

Cement Price Trend for the Second Half of 2023

Asia

The price trend for cement gradually decreased throughout Asia in the third and fourth quarters of 2023. The fall in the cement price trend was gradual during the third quarter but much steeper in the fourth quarter, mainly due to lower raw material costs and inefficiencies in the manufacturing sector.

The consumer demand remained reasonable, but the destocking and oversupply practices taken up by the traders and the slow growth of the construction and industrial sectors of the Asian countries raised doubts about price increases.

Europe

The decline in cement prices across European countries wasn't as sharp as in Asia; the trajectory of the prices still faced challenges, majorly due to the fall in the cost of feedstock materials. Throughout the quarters, prices struggled due to sluggish momentum in end-user industries and pressure from increasing inventories, interest rates, and inflation. In view of limited support from the economic front and rising uncertainties in the industrial outlook of the countries amid the ongoing Israel-Hamas crisis, the consumer sector became skeptical of the future trends of the market, which was evident in the declining price trend of cement.

North America

In the early phase of the third quarter, cement prices in North America treaded downward due to subdued trading and significant drops in export rates. Along with this, decreased production costs influenced by lower crude oil and natural gas prices also impacted the market. However, towards the end of the quarter and throughout the fourth quarter, there was a slight positive shift in price trends, possibly due to renewed consumer confidence in the sector.

Analyst Insight

According to Procurement Resource, the price trend of Cement is expected to be based on consumer confidence in the sector along with the market trajectory adopted by the feedstock industries.

Cement Price Trend for the First Half of 2023

Asia

Cement is the primary building material used in constructing infrastructure, houses, and other civil engineering projects. Produced in a multistep process using limestone, the prices depend on the feedstock prices and primarily the demands from the construction sector. During H1’23, the construction sector saw improvements in the Asian region, particularly China, as the lockdown aftereffects started subsiding. Hence, the spot prices rose by around 8% till the middle of the second quarter. However, the constant supply led to stocks piling up, which led to decreased cement prices in the latter half of Q2.

Europe

In the European Cement market, the prices showed an upward trend for most of the discussed period of H1’23. Italy observed a 4% YOY rise in cement production in June 2023 and an impressive 11% YOY rise in cement prices within the same time. Imports also dropped as domestic production improved. All these factors were majorly attributed to the stabilization in energy and crude oil prices after a long time since the onset of the Russia and Ukraine conflict. Restored supply chains also aided improved exports. Even though the month of May had experienced an even better performance as the prices tumbled marginally in the second quarter, the overall market performance was still promising.

North America

The North American Cement market also witnessed an upsurge in prices, but market fundamentals were disturbed as the demands were high amidst a product shortage. As the energy and pollution compliance became costlier with rigid parameters, and European imports also got expensive, causing the prices to rise throughout the H1’23.

Analyst Insight

According to Procurement Resource, even though the market projections look promising for cement, the demand dependency dictates the market trend for this industry. Thereby, fluctuations are also expected.

Cement Price Trend for the Second Half of 2022

Asia

The price trend for cement recorded an oscillating price trend in the said quarter. Initially, the prices in the Indian domestic market declined as the construction market halted due to the heavy monsoon season and the upcoming festive season. The Indian domestic market recorded a decline of 3% Q-O-Q basis. Cement prices were reduced by 10-50 INR/kg averaging 384 INR/50 Kg bag in August 2022.

However, the price revived in mid-September as construction activities resumed. As the prices of pet coke decreased it increased the profitability of manufacturers. Also, the cement quotations were hiked by 15-20 kg/bag in the eastern and western regions. Similar trend were seen in the Chinese market, where the cement prices averaged 55.95 USD/MT (Spot FD China) (approx..) towards the end of December 22.

Analyst Insight

According to Procurement Resource, cement prices are likely to incline globally. The renewal of demand from the construction industry along with the removal of covid related production restrictions will aid the prices deeply.

Cement Price Trend for Second Quarter of 2022

Asia

As the input cost pressure is intensifying, the Indian manufacturers are now starting to pass down the rising costs, one of the key factors leading to cement price increase in the market. Russia's invasion of Ukraine resulted in an increase in the price of pet coke. The price in the Indian domestic market averaged between 415-450 INR/bag.

Around 60% of the global cement is provided by China. However, during this forecast period, its price trend struggled due to rising coal prices and covid-19 restrictions.

Weather challenges in the Australian mining sector, the Russia-Ukraine conflict, and the Indonesian ban on coal exports to meet domestic demands increased coal prices. The price of Ordinary Portland Cement (Bulk) averaged 475.3 RMB/MT, and Ordinary Portland Cement (Bag) averaged 516.9 RMB/MT in the Chinese domestic market.

Europe

Due to the ongoing political and economic meltdown, cement prices have reached a new maximum in the European markets. The ex-works price in the Mediterranean Basin was the most inflated. Similarly, price trend in Poland rose by 11%, and the Russian prices saw an increase of 25% compared to the previous quarter due to the retaliatory sanctions by the west.

North America

Amidst the rising natural gas prices and the strong market sentiment, the price in the US market remained consolidated since the start of this forecast period, averaging 289.33 USD/MT.

Cement Price Trend for First Quarter of 2022

Asia

Cement prices in India increased in Q1 2022, with the rise in demand as well as an increase in the price of key raw materials like pet-coke. The average cement prices across India observed a 10% rise to 395 INR/kg from February to March and a year-on-year increase of 11%. The rise in price came as construction activities witness a seasonal high with increased road projects announced by the government.

Europe

According to the Turkish Cement Manufacturers' Association's head, the war in Ukraine affecting the cement producers in Turkey, leading to the sudden increase in the price of Newcastle Coal, causing a serious threat to the business. In early March 2022, the price increased by about 100 USD/MT in a single day. According to the association, the cost of cement produced by a plant that uses imported coal would increase by around 15 USD/MT.

Cement Price Trend for Fourth Quarter of 2021

Asia

In 2021, the cement sector, which was harmed by a decline in construction activity, started recovering. India had declared that it will meet infrastructure cement demand with several important projects, increasing the capacity of 14 to 15 million MT. With this global backdrop and China's cement industry capacity in oversupply, foreign investment witnessed significant growth in the region.

Coal prices jumped dramatically at the end of 2021, as did thermal coal long-coordinate pricing. Owing to this, the manufacturing costs grew dramatically in the fourth quarter. The region witnessed an increase of 19% in prices from the previous year. The average cement prices in quarter four stood at 80 USD/MT.

North America

As a result of Hurricane Ida, several US energy plants were offline in October, causing cement production to delay. The export price in North America on an average, declined by about 4% in the fourth quarter of 2021, compared to the previous quarter. Average cement prices stood at 126 USD/MT in the fourth quarter of 2021.

Despite unfavorable year-over-year comparisons and winter weather in California, cement output and price remained steady moving towards the fourth quarter. To alleviate price pressure, the region is transitioning to blended cement, with companies such as Argos USA currently producing PLC at their US locations in Newberry, Florida, Harleyville, South Carolina, and Martinsburg, West Virginia.

Prices in the region had a brief resurgence with a growth of 4% compared to the beginning of the year. According to the cement organization, the recent announcement of a USD 1.5 trillion infrastructure plan in the United States is projected to affect cement prices and production.

Europe

Although infrastructure spending continued to support cement consumption, European economies saw a dip in their once-booming housing markets.

EU subsidies, substantial wage increases, and a pre-election housing boost in Hungary are all key drivers of the industry. With rising interest rates and labor shortages, Poland faced a significant hurdle in transitioning away from coal-fired power facilities.

The French cement sector benefited from a robust resurgence in commercial construction. In the United Kingdom, moderate growth was observed as rising interest rates impacted property demand. The German cement market remained generally stable, with supply chain bottlenecks and lower immigration affecting overall demand. The price in Europe fell by 10% in the fourth quarter of 2021, with average cement prices being 89 USD/MT.

Latin America

The construction industry was the main sector in Latin America that stabilized economies in the final quarter of 2021. According to SNIC, Brazilian cement sales totaled 4.8 million MT in 2021, up by 1.6 % compared to the same period previous year.

The region’s market's growth had been attributed to the continuation of construction and refurbishment through construction, real estate projects, and a tentative resumption of infrastructure projects. In comparison to the previous year, the industry grew by 6.6%. Cement prices were around 100 USD/MT during the fourth quarter of 2021.

Cement Price Trend for First, Second and Third Quarters of 2021

Asia

In 2021, the demand struggled to maintain a high plateau, but gradually descended into a medium trend of fluctuation and decline. Due to the risk of loss induced by new increased production capacity, the prices have remained flat for the previous two years. The prices on the Chinese market increased gradually.

In 2021, 29 production lines with a combined capacity of 48.79 million MT were put in operation, primarily in China.

The resurgence in the construction industries, real estate, and development activities helped elevate the demand in the region. The main stimulus for the cement industry in China, according to China Resources Cement (CRC), were the expanding real estate restrictions.

The Ministry of Industry and Information Technology (MIIT) in China had proposed stricter criteria for cement manufacturers to follow when decommissioning current capacity before establishing new capacity. These policies raised the general cost as producers struggled to absorb increased costs. Because China is the world's largest cement producer, this trend impacted its overall cost.

The rise in pricing was exacerbated by the fact that energy prices in China reached a decade high. There was a 19% growth in cement prices compared to 2020 and the average prices were around 60 USD/MT in 2021.

North America

Cement prices continued to decline in 2021 with the pattern continuing owing to the region also experiencing interruptions as a result of low construction activity and rising fuel and freight expenses.

Additionally, some planned industrial and residential expansion projects have been delayed, decreasing the demand even further. The prices improved in 2021 compared to 2020. The industry witnessed a 3% growth in cement prices from the previous year. The imports increased significantly as a result of supply chain constraints affecting domestic output.

The production declined owing to technical and environmental issues. The availability of relatively non-expensive cement also led to a decrease in the domestically produced cement in the region in 2021. Even when the overall price declined in the region, the average price in 2021 was around 128 USD/MT, an improvement of 9% compared to the previous year.

Europe

Cement production is governed by the EU's increasingly strict emissions trading system in the European Union. Energy prices were a major concern, since the sector's production costs had risen by 25%, and the region's energy prices had been volatile over the past six months in 2021.

Prices rose during the initial quarters of 2021 due to competition from cement importers outside the European Union and the need for a Border Carbon Adjustment Mechanism (CBAM) to compensate for carbon pricing for manufacturers within Europe.

Cembureau, the European cement organization, presented an estimate indicating that if the EU ETS Carbon dioxide cost increased further, it would account for 12 to 15% of cement manufacturers' production costs. The average price in 2021 was around 92 USD/MT, an increase of 7% year on year from 2020. In early 2021, cement prices were around 99 USD/MT, which declined to 89 US/MT by December 2021.

In Europe, the industry walks on a tightrope between remaining financially sustainable and moving towards net-zero emissions.

South America

In South America, sales increased significantly during the coronavirus pandemic, owing to a broad recovery that began in 2020 and relatively lax lockdown measures in comparison to other nations. Companies such as Holcim, CSN Cimentos, Cimentos Mizu, Cimento Apodi, InterCement, and Votorantim all contributed significantly to the region's pricing and demand growth.

Demand nearly quadrupled to 6.42 million MT in the first half of 2021 from 3.33 million MT in the same period of 2020 and was much higher than the 4.94 million MT reported in the first half of 2020. Argentina had the highest prices, followed by Nicaragua, Uruguay, Guatemala, and Paraguay, where prices reached about 100 USD/MT. Despite high demand, cement prices in Brazil were lower than in other South American countries.

Cement Price Trend for the Year 2020

Asia

The global pandemic affected the product’s prices in an unprecedented manner. The prices fell sharply during the first two quarters. Towards the end of the year, the prices recovered and stabilized. In China, bad weather also hampered the growth of the industry. Despite the adverse conditions, the production in China grew by 2%, according to the Global Cement Organization. CNMB and Anhui Conch were some of the largest producers who had an increased revenue with an increase in their domestic sales. In 2020, the prices in Asia fluctuated between 50-60 USD/MT

The prices increased by 8% in the third quarter and 3% in the fourth quarter of 2020 and continued to increase after the sudden drop in prices in the first two quarters.

The strict regulations imposed by the Chinese government caused some old factories to reduce or close their units to comply with the new standards. This ultimately had an impact on the prices in the region. Due to strong market control, China's cement industry improved as a result of the elimination of backward production capacity and the improvement of industry concentration, and the overall price also increased.

India also faced similar tribulations during 2020. The production in the country declined along with demand in the first two quarters of 2020. Prices increased by more than 10% towards the end of the year. The price elevation was exacerbated by factors such as power outages and rising coal prices in 2020.

Countries like Vietnam underwent a poor first half reduced prices of the product in 2020 owing to oversupply and decline in their sales volume. The situation improved majorly due to close market tie-ups with China and the Chinese public investment plans.

North America

Hurricanes and tropical storms prompted turnarounds at many cement plants in 2020. The pandemic had a negative impact on the manufacturing industry's price. The pandemic accelerated an already-declining value of residential and non-residential development, lowering demand for industrial commodities in 2020.

This affected the cement industry as well. Prices fell 10% in the second quarter of 2020 compared to the first half of the year. In most regions, the production remained below capacity. In 2020, there was a 14% year on year decline in prices compared to the previous and the average prices were recorded around 118 USD/MT, fluctuating between 132 USD to 110 USD/MT.

In April, some cement factories in the United States were shut down due to reduced demand caused by pandemic restrictions. Despite its ongoing infrastructure projects, Canada also saw a drop in demand. The prices were under tremendous pressure due to stringent covid restrictions and demand volatility.

Europe

With the cement industry hit severely by the Covid-19 Pandemic in 2020, the region’s prices were disturbed by strict lockdowns in Italy, France, Spain, and the UK. Prices fell initially in the second half of 2020. Owing to stable demand in Eastern Europe and Northern Europe, the prices began to recover.

The prices increased by the second half of 2020 in several regions. Government benefits initiatives were coming to an end as a result of rising debt levels. Due to the high cost of emissions, the prices increased. Prices in Europe were around 87 USD/MT in 2020.

Latin America

Demand for this product in South America was robust in 2020. The consumption in the major countries of Brazil, Colombia, Peru, Argentina, and Chile had been boosted in the first half of the year by building, solid property sales, and the reactivation of public works.

Additionally, consumption increased significantly year over year in 2020 as a result of corporations having relaxed COVID-19 restrictions in the region.

In June, in Chile, bagged cement sales climbed by over 67% year over year and increased by more than 20% since early 2020.

While the demand in Brazil had been rising since 2020, COVID-19 caused a sharp decline in demand in Argentina and Peru in the first half of 2020, which then improved due to a recovery in the construction sector, fueled by both private and state activity.

The demand climbed by more than 31% month over month and 18% year over year in 2020, increasing by more than 34% from 2019. Price improvements in Brazil and Colombia resulted in a price increase of more than 76 USD/MT in South America in 2020.

Procurement Resource provides latest prices of Cement. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Cement

Cement is a binding material used in building and civil engineering construction that sets, hardens, and adheres to other materials. Hydraulic cements set to a hard mass when combined with water owing to hydration, that is, a chemical combination of the compounds in cement with water. Among different cement types, Portland cement is most widely used across the world. Portland cement is essentially made up of compounds of lime, mixed with silica and alumina.

Cement Product Details

| Report Features | Details |

| Product Name | Cement |

| Industrial Uses | Mortar and concrete, Manufacture of bricks, tiles, and shingles, Pipes, beams and railroad ties, Extruded products |

| Supplier Database | CEMEX S.A.B. de C.V, HeidelbergCement AG, CNBM International Corporation, InterCement Participações SA, Anhui Conch Cement Company Limited, Cementir Holding N.V, Cementos Molins, S.A., Buzzi Unicem SpAUltratech Cement Ltd. |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Cement Production Processes

- Production of Cement via Industrial Process

Cement manufacturing process involves various steps, which starts with mining, crushing and grinding of raw materials like limestone and clay, to a fine powder, called raw meal. The obtained product is then heated in a cement kiln at a temperature as high as 1450 °C. This is followed by clinkerization, cement grinding and storing of the finished product.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Related News

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com