Braskem Opens New Polypropylene Facility Amidst the COVID-19 Pandemic

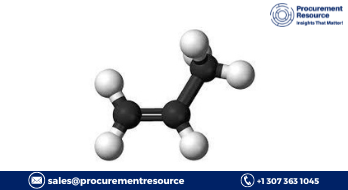

Braskem, the largest polyolefins manufacturer in North America and the leading producer of biopolymers in the world, has recently announced the successful launch of commercial production at its newest, world class polypropylene (PP) facility in the city of La Porte, Texas. The launch was followed by the recent launch of its new INSPIRE polypropylene (PP) grade designed to replace polyethylene terephthalate (PET) in packaging products such as ready-made meals at grocery stores and restaurants when higher temperature resistance was required.

The construction of this world class facility began in October 2017 with the final phase completing with the last mechanical construction in June 2020. This launch of commercial production has not only successfully completed the commissioning process but has also achieved Braskem’s high-quality assurance protocols.

Braskem’s new line of production has a capacity to manufacture over 450 kilotons or 1 billion pounds per year. It also has the capacity to produce the entire polypropylene portfolio, which includes a broad range of products such as impact copolymer, random copolymers, and homopolymers.

The launch of Braskem’s commercial production at their world class polypropylene production line in La Porte has affirmed Braskem’s position as the leader in the North American polypropylene market.

With an investment of USD 750 million in this project, the facility has become the largest polypropylene production line in both North and South America and the first new polypropylene plant in North America since 2008. The facility ensures a long and sufficient supply of polypropylene for its clients.

While constructing the polypropylene facility, Braskem kept its commitment towards sustainability and paid attention towards eco-indicators such as emissions, energy efficiency, and water, as well as waste reduction and recycling.

North American Polypropylene Market Amid COVID-19 Outbreak -

Industry participants from the North American polypropylene market such as Braskem, Asahi Kasei, ASI Gem plastics, Aurora Plastics, Avangard Innovative, ExxonMobil, Formosa, INEOS, LyondellBasell, Pinnacle Polymers, Phillips 66, and Total Petrochemicals, among others, believe that PP could combat challenges currently faced by the industry due to the COVID-19 pandemic. This deduction is due to the rising demand for polypropylene because of its properties like resistance to high temperatures, high tensile strength, and corrosion resistance.

The increasing demand for packaging solutions from the food and beverages industry has facilitated the growth of the market during the lockdown period. The growing consumption of packed food, such as snacks, biscuits, and chocolates, has further boosted the growth. The rising application of polypropylene in the automotive industry due to its effective sealing, easy processability, and stiffness properties has also increased its demand in North America.

The manufacturing of fashion apparel, sports equipment, toys, pipes, agricultural tools, electrical appliances, and plastic based products, among others, will also enable a speedy expansion of polypropylene in the North American region.

The start-up of the polypropylene manufacturing facility by Braskem in La Porte, Texas, is significantly going to balance the supply and demand chain of polypropylene in the North American PP market. The disturbance in demand, as well as other operating challenges, are present due to the COVID-19 outbreak. However, the market has now adapted to the COVID-19 pandemic, and demand in North America is recovering fast to pre-COVID levels.

The construction of this facility has also positively facilitated in avoiding the economic crisis caused by the COVID-19 pandemic in the Texas Gulf Coast region by employing over 1000 development and construction workers.

In order to support the sustainable use of polypropylene through the development of and investment in the circular economy, Braskem’s new facility will also boost the United States’ polypropylene recovery and reuse.

.webp)